We have adapted a standard hydraulic throttle valve together with a pump for use as a load-testing unit for gearboxes, after we have finished gearbox assembly. Usually, hydraulic throttle valves are used to change the speed of oil in hydraulic system, but when these devices first became available we discovered a dual functionality inherent in this mechanism. This alternative application can be useful in the industry.

The reason for testing gearboxes is to check their noise and temperature levels, vibration, strength of materials, conditions of various design details, and especially the operation of the gears in the unit. It is often necessary to recondition the gears to provide still finer surface finishes and accuracy for the gear teeth gear after a hobbing operation has been completed.

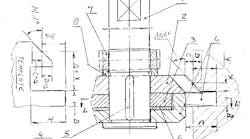

We recognized that the hydraulic throttle valve offers a gap detail that we use to adjust loads by turning a handle. Following is the principle outline of our testing stand.

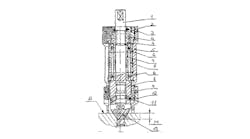

The stand is situated on a large steel plate on the welding table, and on this plate stand we mount an electric motor, the testing unit, a pump, and a standard hydraulic throttle valve. Below the plate is an oil bath and a filter for the pump; a smaller bath with a filter; and small pump for the lubricant unit, with a small electric motor.

The electric motor rotates the testing unit with a coupling. The unit rotates the pump through the coupling, with the pump providing pressure oil from the oil bath through a pipe to the hydraulic throttle valve, and back to bath. By turning the handle of the hydraulic throttle valve we change the load on the testing unit.

On the plate we mount a manomoter, a wattmeter, and all the devices that we need for testing units according to the relevant gear application.

Some further details:

1. In order for the pump to rotate in one direction we need to use a small gearbox with a handle to change the revolutions per minute on the reverses and running light. This box remains constantly before the pump and rotates the pump when the testing unit rotates the small gearbox.

2. To make the testing unit easy to carry, the unit and electric motor can be mounted with bolts separately on the two plates. It can be positioned the big plate using the guide, and fixed by screws to the big plate at the time of the examination.

3. The system’s hydraulic pump and throttle valve also can be used as a brake for any mechanical unit.

To summarize, we have been effectively using a hydraulic throttle valve for load-testing different geared units for long time, and it can be used effectively by any company: a mechanical designer can easily design an effective testing stand.