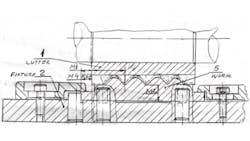

Sometimes tool-designers must design complicated profile milling cutters to complete a machining task (see above sketch, 5.)

If a profile is no more 10 mm (0.3937 inches) deep, some designers make this cut using just one milling cutter (1), rather than dividing the step for separate cutters.

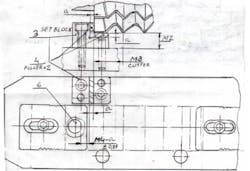

In this case, to make one cutter more economically, we invested less in materials, time, and money .

In calculation, to use the dimension of work M1, M2, M3 of the cutter, M4 = M1 - M3, M4-a is the distance from pin 6 to set block.

About the Author

Mark Grizotsky

Owner

Mark Grizotsky, owner of MLG Tool Design in Willowdale, Ontario, has been a major contributor and influencer to machinists everywhere with his insights to machine design and set-up, tooling design and selection, and advice for preparation and processes.