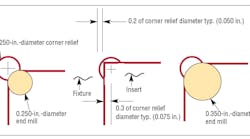

My idea eliminates the conventional "Mickey Mouse" ears when machining corner reliefs in pockets. I reposition the centers of cornerrelief diameters and produce neater reliefs with built-in safety factors that keep insert corners from touching relief-diameter circumferences.

I machine my corner reliefs before cutting pockets using end mills up to 1.4 times larger than the corner-relief diameter end mill. For example, I use a 0.350-in.-diameter cutter for machining pockets with 0.250-in.-diameter corner reliefs. Also, my smaller relief diameters give chips no room to collect when machining.

Alan Ramsay

Rochester, N.Y.

www.aminfo.biz/412.ad

Latest from Practical Ideas

Latest from Practical Ideas

Practical Ideas

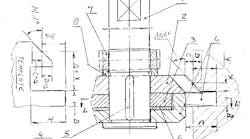

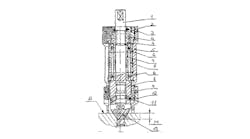

Countersinking with a Stop Mechanism

Sept. 5, 2012