Job shops are among the types of operations that are likely to anchor domestic manufacturing, keeping it vital in global economy, but that doesn't mean that job shops don't have to compete with the rock-bottom labor and production costs set by foreign competitors. As offshore competition continues to squeeze the manufacturing sector, many job shops are turning to technology to help stay competitive in a worldwide market.

A savvy use of technology and a skills advantage are two things that will keep job shops profitable even as the trend of outsourcing continues. At Software Advice I examined developments in job shop manufacturing to find out which technologies enhance their skills advantage. I noted five technologies that are at the forefront of driving competition: 3D computer-aided design (CAD), laser cutting tools, shop floor software, iPad workforce integration, and outsourced marketing firms.

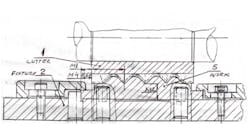

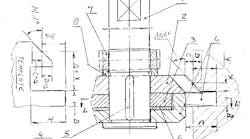

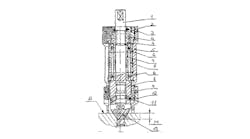

1. Laser cutting

Laser cutting has been around for some time but it hasn't been a very affordable technology, especially for smaller job shops, until recently. It’s a great capital investment for job shops. As laser-cutting technology moves downstream, shops are able to take advantage of faster and more precise cutting capability. This technology greatly improves the efficiency of metalworking, especially given the fact that it can be linked to a CAD program to allow machine-guided cuts. Additionally, laser-cutting tools can cut multiple materials (wood, aluminum, plastic, etc.) with no need to change machines. It is a great technology for both small contracts and volume orders.

2. iPad software integration

The iPad is arguably the hottest piece of consumer tech around. In the manufacturing industry, that’s not quite true. However, job shops are starting to come around and adapt the iPad to improve their business processes. The iPad can be a great productivity boon on the shop floor.

Consider this: a worker at his station can pull up work orders directly from his table to view instructions on how to complete a project from the iPad. Once the job is done, the labor hours can be logged immediately into the shop’s tracking system, and the next job can be pulled up on the tablet. This creates real-time worker knowledge and timely information for managers.

3. Outsourced marketing

Let’s face it: the skill set of job shops is in building things, not creating compelling marketing literature. Service firms that play middleman between original equipment manufacturers (OEMs) and job shops can be a great way to bridge the gap between manufacturing and marketing. The service firm Manufacturing Mart is a great example, as they not only handle marketing and lead generation efforts, but they’ll also design and prototype the product, if requested. Outsourcing these time-consuming tasks can be a great benefit to job shops and allow them to focus singularly on production. The outsourced firm is likely also better than the shop itself at finding the right kinds of clients.

Derek Singleton writes about various topics related to ERP, with particular interest in the manufacturing and distribution software markets at Software Advice, a blog that helps buyers locate the best software for their business. Learn more about the ideas listed here and other technologies for job-shop competitiveness, follow him on Twitter at @ERPAdvice, or email Derek at [email protected]