Machine tool builder Mori Seiki opened a new U.S. headquarters recently, celebrating the occasion with a four-day event that drew more than 2,200 visitors to the state-of-the-art center in Hoffman Estates, Ill. The new center was inaugurated with a ribbon-cutting ceremony attended by Dr. Masahiko Mori; George Hiseada, Consul General for Japan, and Hoffman Estates Mayor William McLeod.

During the event, 19 different seminar topics were presented in the location’s 100-seat auditorium, with guest speakers from the automotive, medical and energy industries sharing strategies for success.

Also, Mori Seiki presented a series of machining demonstrations, seminars, and tours of the showroom, conference facilities, and Mori Seiki University.

Mori Seiki University’s Learning Lab houses three of MSU’s seven machines installed for hands-on training, including NL2500, DuraTurn2550, and the multi-axis NZ2000T3Y3. MSU also includes classrooms and worktables that accommodate entire subassemblies, so students can study machine maintenance.

The new showroom, quality control room and workroom comprise 40,000 square feet of the new headquarters, about 40 percent of the total space. During the Grand Opening, Mori Seiki featured cutting demonstrations with 23 machines under power, plus two skeleton models to demonstrate design features of the NMV and NT Series.

Five new Mori Seiki models were introduced at this event, including the NMV1500DCG, NMV3000DCG, NT1000, NV7000 and NVL1350T.

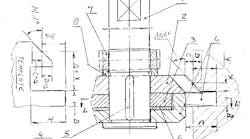

Mori Seiki’s smallest machine in its five-axis VMC series, NMV1500DCG, showed high-speed machining of a 2-inch automotive turbo impeller. The short cycle time was achieved with a 60,000-rpm spindle and a high-speed rotary table.

Also introduced was the five-axis NMV3000DCG. It has an optional 34-pallet workpiece changer, for parts up to 11.8 inches high and 13.8 inches in diameter.

Mori Seiki’s smallest mill/turn machine, the NT1000, was shown machining two titanium parts for a medical implant as a set, in one set up. The NT1000 features a 20,000-rpm spindle and built-in CAM for 5-axis programming.

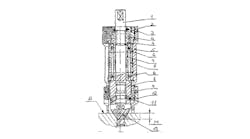

The NV7000 vertical machining center has a large-axis travel and 67 x 30-inch table. It’s a heaving-cutting design with a high-horsepower, 50-taper spindle and guideways that are nearly two-and-a-half times larger than conventional machines.

Finally, Mori Seiki introduced its NVL1350T vertical-turret lathe, a precision VTL designed for heavy loads and large-diameter disks — such as are required in construction, aircraft, ship and large bearing applications.

Mori Seiki also hosed over 20 of its Mori Seiki Qualified Peripheral (MSQP) suppliers, who exhibited tooling, workholding, accessories and other services to provide complete manufacturing solutions. The MSQP program identifies suppliers and products that meet Mori Seiki standards of performance.

Also, Mori Seiki introduced the newest version of its CNC software, MAPPS IV. The latest release supports more diversified and complicated workpiece production with built-in CAM software and post-processor for 5-axis programming. Optional in-machine cameras, integrated 3D machine models, more tool data, and built-in troubleshooting functions are other new features of MAPPS IV.