Chuck Buski

Phoenixville, Pa.

I often need to shim various pieces of tooling to adjust their heights after they have been sharpened. When I make my shims, I prefer a precise fit with no slop around the dowel holes. This locates the shims perfectly.

First, I cut a piece of shim stock to the needed size and lay it under the block needing shimmed and transfer the holes using the appropriate transfer punch for obtaining accurate hole location. Then, using a standard shim-stock hole punch set that has nine fractional sizes, I locate the shim stock in the punch block/die set exactly where it needs to be to line up with the tooling being shimmed using the same size transfer punch as the hole I'm punching. While keeping pressure on the shim, I remove the transfer punch, install the shim punch and punch out the hole for a precise fit.

Latest from Practical Ideas

Latest from Practical Ideas

Practical Ideas

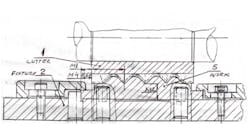

Countersinking with a Stop Mechanism

Sept. 5, 2012