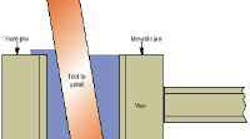

For grinding various HSS tools, I've developed simple method involving a fixed vise and special angled wedge plates.

The wedge plates rest against the fixed and movable vise jaws to clamp tools at the desired angle for grinding.

I use several different sets of angled plates. Each is for a particular tool I often grind. For instance, I have a 7° set for O-ring grooving tools ones for form-tool reliefs.

P.S. Ramdas

Kerala, India

Getting an angle on screw cutoff

Cutting socket-head cap screws to a custom length is an irritating, yet often necessary, job. Doing it with a hacksaw runs the risk of slipping and smashing a finger. When using a vertical bandsaw, the blade binds, and its teeth rip out. What I use to easily cut these screws is a horizontal bandsaw.

I clamp a piece of angle iron in the saw's vise as close as possible to the blade. Holding the screw with an Allen wrench, I brace the cutoff end against the angle iron's inside corner and slowly lower the blade, cutting off the screw.

Roger Schicker

Georgetown, Del.

Pick the winning Practical Idea!Select the best Practical Idea in this issue by circling the associated number on the reader service card. Winners receive an award of $100. An honorarium is paid for each item published in this column. Submitted ideas are subject to editing, and sketches will be drawn to conform to AM's style and format. Submission of clear, close-up photos is encouraged. Send material to Practical Ideas, AMERICAN MACHINIST, Penton Media Inc., 1300 E. 9th St., Cleveland, OH 44114-1503. Please include your name, address, zip code, and Social Security number. Winner for April2004: NoshirKapadia, Putting the squeeze on tight threads, p. 72. |