As a machine rigger, I needed a quick and easy way to move two Bridgeport knee mills around the shop floor, and instead of using pipe rollers, I built a set of wheels and axles for the job. Prior to my new method, I wasted about 20 min moving each machine. With the new system, I can move a machine 100 ft in the same amount of time it would take to walk the distance.

As I used my wheels and axles method, many shops asked where I got them from and could I get them a set. With that said, I made a bunch of them and decided to see how they would sell. They were a hit, and are now available under the name WheelsForMachinery at (www.wheelsformachinery.com).

Ed Reid

Latest from Practical Ideas

Latest from Practical Ideas

Practical Ideas

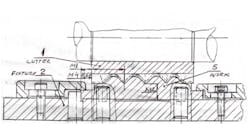

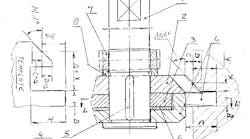

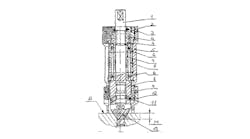

Countersinking with a Stop Mechanism

Sept. 5, 2012