Metal chips often lock up the screw and nut mechanisms on manual vises mounted to milling machines. When this happens, I must dismantle the assembly and clean it, wasting valuable machining time.

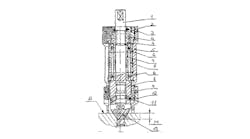

To eliminate this hassle, I use a custom-made guard that deflects chips off the vise.

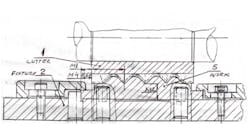

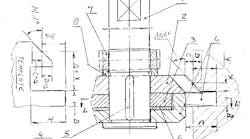

I drill and tap 1/4-20 holes in the top of the vise at the front and back. I then mill a 0.250-in. slot in a piece of 8-in.-long, 0.060-in.-thick steel. The slot is 5-in. long (maximum jaw opening), 0.500 in. from the edge of the steel, and on center.

Using 1/4-20 screws, I attach the steel piece to the vise and bend it over the jaw edges to cover the vise's side openings. For the back jaw, I bend a small piece of steel 90° over the back of the vise to protect that end.

Steven Saxer

Arlington, Tex.

www.aminfo.biz/404.ad

Pick the winning Practical Idea!Select the best Practical Idea in this issue by logging on to the associated URL. Winners receive an award of $100. An honorarium is paid for each item published in this column. Submitted ideas are subject to editing, and sketches will be drawn to conform to AM's style and format. Submission of clear, close-up photos is encouraged. Send material to Practical Ideas, AMERICANMACHINIST, Penton Media Inc., 1300 E. 9th St., Cleveland, OH 44114-1503, or e-mail to [email protected] Please include your name, address, zip code, and Social Security number. Winner for July 2005: Tony Grant, "A shim-stock organizer," p. 60. |