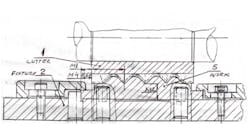

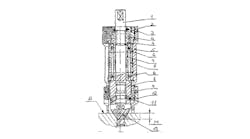

Shops that machine aluminum often must deal with splashes and leaks when using coolant. One suggestion on how to minimize such messes while still providing enough coolant to keep cutters from gumming up with melted aluminum chips is a drop-type system.

These systems deliver large drops onto workpieces and cutting tools at evenly spaced intervals – just enough to keep some lubrication on the work, but not enough to make a huge mess. Some systems go through as little as couple of tablespoons to an ounce of coolant every eight hours and, quite often, the coolant is a safe vegetable-derived product.

Coolant can be expensive for drop-type lube systems, but since so little of it is used, it’s much more efficient. And there’s less fog and mist. Along with the drop-type lube systems, some shops suggest using carbide-coated tools made specifically for aluminum and running them at the tooling manufacturer’s suggested speeds and feeds for aluminum.

From the pages of

Practical Machinist.com