Usually machine shops have more than an obvious reason to make improvements on the big jobs. The biggest benefit may be the ripple effect that change has on the rest of the shop’s workload. For example, consider what happened when Shaw Industries in Franklin PA, suddenly faced a rush order for a family of 16 large, injection mold blocks. On that job alone, retooling the cavity-hogging operation shaved a week off the delivery schedule and about $10,000 in machining costs. Now, the shop is applying the same practices plant-wide, and expects annual saving to be over $100,000.

“And it is just a drop-in retooling,” shop foreman Steve Knight said.

The new tool — an Ingersoll Gold-Quad F facemill — seemed an unlikely choice for Shaw’s applications. Introduced about two years ago, it is nominally a high-feed tool tailored for fast, shallow passes. Yet at Shaw it is excelling at depths of cut approaching 0.100 in. Other mold shops using the same tool are running this hi-feed facemill as deep as 0.075 in. Running 22/5, the 37-man mold and welding shop is accustomed to big work, including structural fabrications weighing up to 15 tons.

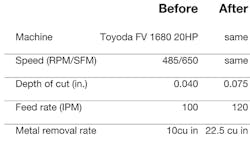

“We were moderately satisfied with our rough milling processes on hardened mold blocks,” Steve Knight recalled, “but we always felt there was a better way.” Their standard parameters with a 3-inch facemill had been 485 RPM (650 sfpm) 0.040 in. depth of cut, and 100 IPM. Whenever they pushed further, the inserts would shatter, and very often that triggered a cycle of reworking parts and repairing the cutters or fixturing.

It was the big mold order, with its tight schedule, that prompted Knight to look for a better way. Each of the 16 blocks measured 24x36x8 in., weighed about a ton, and required hogging out 600 lb of hardened P20 material to create the mold cavities. “Five tons of stock to remove in all, with not much time to do it,” Knight added.

He tried out one new cutter. It improved the removal rate slightly but the inserts wore out too soon and cost a lot more. So he asked Josh Jolley of Allegheny Tool and Supply for a better solution. Jolley brought in Dennis Hawke of Ingersoll to demo the Gold-Quad F. Based on experience, Hawke was confident that the new tool could increase throughput at least 25% and be just a drop-in replacement.

“Though primarily a high-feed tool, it has proven out in scores of deeper-cut applications, so we were confident it would work,” said Hawke.

In the trials, with Hawke’s and Jolley’s guidance, the parameters were ramped up gradually up to balance removal rates and edge life. In the end, the new cutter nearly doubled the removal rate with absolutely no insert fractures. Edges looked as good as new after several passes. The operation also ran more quietly. Check these results:

“This was definitely a tool and process worth applying plant-wide,” said Knight. “The same cutter body accommodates a surprising variety of inserts to match different conditions, including contouring.”

Since that initial mold-block job in February, in fact, Shaw has used 3- and 5-inch Gold-Quad F facemills for rough milling, both flat and contour, on a variety of steels and stainless steels. “It has benefited our enterprise-wide profitability way beyond that first job.” Said Knight.

One recurring application has been shanking of forging dies. “Based on what I’ve seen, I’m sure we could run this tool at these depths and 180 IPM on many softer steels.”

The Ingersoll Gold-Quad F facemill may seem an odd tooling choice for this deep-cut application. Classified as a high-feed tool, it is known better for quick, shallow cuts. Yet at Shaw, each pass removes a depth of 0.075 in. “That’s definitely beyond the ‘comfort zone’ for a typical high feed tool,” Hawke explained. “This is really an all-purpose tool.”

Introduced less than two years ago, the Ingersoll Gold-Quad F family of facemills has become the “go-to” solution for a variety of high-feed rough facing, profiling, and interrupted-cut applications. It accommodates a complete selection of inserts suited to a wide spectrum of materials and machining conditions. As a result, it has become one of Ingersoll’s biggest sellers in a very short time.

The cutter uses an extra-thick insert and extremely rigid seating for durability and process security. Insert geometry takes advantage of chip thinning for faster feeds, and also features high positive rakes plus 12-degree lead angle to reduce lateral cutting forces. Center-screw clamping design facilitates unobstructed chip evacuation. Finally, a proprietary post-coating technology smooths the surface and strengthens the bonds between coating and substrate to improve performance 35% on average.

“The low spindle load readings at Shaw definitely demonstrate the tool’s free cutting geometry,” Jolley added. “That’s what enables such deep cuts without stalling or overloading medium duty machines.”