There is no tooling cure-all for the problems of machining deep cavities, deep holes, or deep slots. Chip evacuation, lateral forces on long unsupported shanks and the risk of chatter inherent in long-reach machining simply compound the basic challenges of cutting metal.

However, machine shops across North America have experience that shows there are good workarounds for common long-reach machining operations — techniques that can improve material removal rates and protect the tools in such adverse conditions.

“The keys to success are tight machines, free-cutting tool geometries that minimize lateral forces, extra attention to chip evacuation and extremely rigid shanks and extensions,” advised Mike Dieken, Ingersoll Cutting Tools’ milling product manager. Take a closer look at a variety of long-reach success stories.

Roughing Deep Cavities — Up in Canada, two mold shops that once relied on standard button cutters to rough machine 18- to 22-inch mold and mold cavities have sped that process up by at least 2 to 1. What made the difference in both plants is an advanced, IC face mill with unique insert geometries, mounted on extra rigid extension shanks.

The inserts on the Ingersoll H-Feed Mini mill look like rectangles with radiused ends, enabling a smaller cutter to go full speed through the straightaways and deeper into corners than a larger tool can do. The extra-rigid carbide Inno-Fit extensions feature a self-centering, three-point coupling design and large-surface contact area between segments. Feed rates average 400-900 IPM depending on tool diameter, versus the previous 50-100 IPM respectively.

Said Tom Hunt, manufacturing supervisor at Reko Manufacturing Group, Windsor, Ont., “We do the cavity work on five-axis machines, where the tooling deficits inherent in button cutters become painfully obvious. We had to slow down in the corners before, but not at all anymore.”

Lead machinist Jay Noble at Redoe Mold, also in Windsor, said, “We’re milling at the bottom of a cavity as fast as we would with a stubby tool on a surface cut.”

Plunge-Milling Recessed Flats — More than 20 of the large iron castings processed at Hole-Mac Inc., Bay City, Miss., require milling the bosses 15 inches down between the webs. Because of the long unsupported tool shanks, conventional radial carbide mills frequently ruptured, triggering a chain reaction of broken inserts and often created tool wrecks that once blew out a spindle. “The long reaches made it a very unstable operation,” said John Scarbrough, manufacturing engineer. “The chatter was a dead giveaway.”

The solution was a face mill that orients the inserts tangentially, thereby aligning the main cutting forces with the inserts’ strongest axis.

Increasing Tool Life, Eliminating Failure

“Milling recessed flats is essentially a plunge milling job, for which a tangential mill is ideally suited,” according to Ingersoll’s Don Yordy, S-Max product manager. So the tool developer recommended an Ingersoll S-Max tangential face mill, which now features more free-cutting inserts. The switch not only doubled throughput on the recessed bosses, but it also eliminated all catastrophic tool failures. “Now we replace the inserts due to predictable flank wear only,” Scarbrough said, “and the operation runs very quietly.”

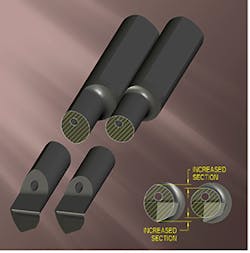

Deep Boring — In bores of any depth, cutting conditions are apt to deteriorate because there’s rarely enough room for both a sturdy tool shank and decent chip evacuation. As a result, tool selection necessarily becomes a compromise. Besides this, the machined surface is concave, which complicates formation of free-flowing chips.

However, a new boring tool with an elliptical shank and high-shear cutting edge, called the Ingersoll T-Micro system, eliminates the compromise. The long axis of the boring bar lines up with the main cutting forces, enhancing rigidity in deep-hole work. The short axis expands the chip-clearance areas.

A telling example of this principle at work shows up on a very challenging deep boring job on a tiny medical part made at Medfab Manufacturing, Lakeville, MN. “Titanium tubing, 4:1 aspect ratio, walls thinner than a fingernail, close tolerances, and a 20µ finish requirement on the entire ID: that makes for a ‘perfect storm’ of machining headaches,” the production engineer said.

With all previous tooling schemes, the boring operation took three and a half minutes per part, at best, always followed by 15 minutes of hand polishing. Moreover, the as-machined finish deteriorated so quickly as to require tip replacement every 30 pc.

By contrast, T-Micro tool completes the part in less than three minutes and leaves an 8- to 10-µ as-machined finish, which needs no hand polishing whatsoever. And, the tip lasts through at least 250 pc.

Deep Cavities in Plastics — Many plastics fabricators still shy away from indexable carbide (IC) tooling because of the initial cost, and rely instead on HSS. However, one Illinois plastics shop took the leap to IC tooling for routing operations on some deep cavities. For their reward, they have increased throughput by five-fold and gained payback on the cutter body on the first job. Then, they began applying IC tooling systematically on other milling, turning, and holemaking jobs — and they have never looked back. On average, using a variety of Ingersoll IC tools in place of solid HSS tools, this shop has reduced enterprise-wide machining costs by 30%. The average gain in material removal rate is 2 to 1, even on ‘gummier’ nylons, delrins, and polyesters. And, because the processes do not overheat the workpieces, part integrity has improved, too.

Also, the cutting action of IC tooling is inherently gentler on the workpiece than HSS tooling because the cuts are generated progressively, ‘nibbling away’ the material. “The IC machining process substitutes higher spindle speeds and faster feeds for deep cuts,” explained Forman, who helped coordinate the tooling conversion.

Because the polymers are so much softer than any metal, the inserts outlast carbide tools by orders of magnitude, and the cutter bodies look as good as new after several years. “The cutter bodies are truly one-time items, which qualify them as capital assets on our books,” said the company president.

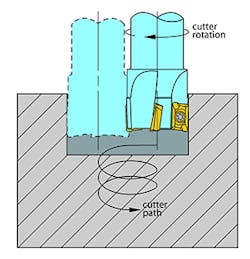

Long-Reach Holemaking — In large fabrications and casting, a hole is needed that is shallow, but located deep inside a cavity or down between the webs. If the hole is large enough to accommodate a milling tool, orbital milling with a solid carbide tool is the usual solution. However, a tool that enables full “corkscrew milling” often may speed up the operation.

A case in point: drilling large steel castings at Baldor Electric Co., Gainesville, Ga. The holes lie ten or twelve inches down between the webs. Previously, the company went the conventional orbital milling route. Switching to corkscrew milling with an Ingersoll Deka face mill on a rigid shank tripled the metal removal rate and improved tool life by 20 to 1. Geometry of the tool enables continuous advance and orbiting. High positive rake on the insert reduces cutting forces, especially radial forces, to increase tool life.

“Corkscrew milling also can open holes in solid metal,” Dieken said, “but extra attention to chip clearance may be needed, especially in vertical setups. On horizontals, the chips often clear by themselves.”

About the Author

Doc Ardrey

Principal

Doc Ardrey is a veteran writer on developments and trends in the design of cutting tool products.