Touch technology is revolutionizing human interaction to complex devices, speeding and simplifying individuals’ approach to problem solving. Touch technology is available now for one critical manufacturing function — the coordinate measuring machine.

It’s long been the case that CMM software is too complex for most manufacturing tasks, requiring long training periods and extended learning curves. TouchDMIS™ is a full-featured CMM software with intuitive touch interface, offering unparalleled user experience and benchmark CMM productivity.

Developed for both manual and CNC CMM’s, including portable arm CMMs, TouchDMIS brings some novel, and time-saving features to the task of product verification. Standard CMM software programs provide access to functions through complex systems of toolbars, dropdown menus, and window selections. TouchDMIS offers a user interface based on “smart” technology, wherein “next suggested functionality” is presented dynamically for user confirmation. This minimizes learning time to just a few hours, with immediate advantages for productivity benefits.

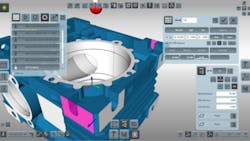

The program also represents an innovation in software functionality for industrial metrology applications. It reduces traditional CMM software to just eight function buttons that, when selected, open an appropriate function window; the button is integral to the open window, providing one touch re-docking.

The 64-bit, multi-thread software (Microsoft® WPF and Direct X®) maintains all windows, live, even when docked.

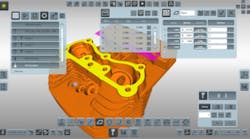

All open windows offer ‘thru-view,’ so displayed graphics remain visible, and many windows offer ‘flip button’ to displays of further advanced functions and capabilities that expert users may seek. The software graphics area bleeds to the edge of the touch screen, with all software buttons floating atop the graphics.

Automatic Determination, No Interaction

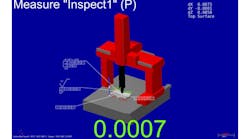

The Measurement Wizard automatically determines the feature under inspection, negating any user interaction and offering hands-free CMM inspection. Touch selection of graphically displayed measured features launches the Construction Wizard and displays all available legal metrology options from the selected features.

TouchDMIS integrates the ISO-standard DMIS programming language and presents this complex high-level CMM language in a simple, readable block format, so users need not interact directly with the DMIS language code. TouchDMIS can use DMIS programs from older generations of DMIS-based CMM softwares, providing a migration path and full CMM program interoperability.

Touching any software input field launches the virtual keypad, offering smart-phone productivity on the CMM. Tolerancing measured features is achieved with a single touch from the Tolerance Table; ISO tolerances also are available.

TouchDMIS graphics offer a rich representation of measurement actions, offering an intuitive and informative guide to measuring tasks. The CMM Touch & Drag Disc allows go-to-path motion to be programmed and individual touch points adjusted within a measured feature. Full-part program simulation with motion path simulation, collision detection, and the complete virtual Renishaw Probe library add to the virtual program prove-out experience.

CAD Simplified

CAD has traditionally added further complexity to CMM softwares. The optional TouchCAD module of TouchDMIS simplifies CMM programming when using CAD data and introduces touch-screen manipulation of the CAD model using gesture commands.

CAD entities are selected from the model with a single touch. Step and IGES files are imported as standard and native CAD geometry import from all popular formats is also available.

TouchDMIS offers a choice of Inspection Reporting functions, including Blueprint Reporting, traditional analytical and graphical reporting, as well as SPC, Excel® and XML outputs.

Blueprint Reporting is a novel, shop-floor friendly method of creating intuitive reports that correlate to the original part blueprint. The screen displays a graphical representation of inspected part features; dimensions can be touch-extracted from the graphics and displayed in blueprint format providing a DNA blueprint of the actual measured parts with colored G D & T, indicating feature status.