OEE stands for “Overall Equipment Effectiveness” and is an important metric for many companies’ initiatives to establish “Operational Excellence.” There are many different definitions for OEE but it is largely understood to be a composite metric based on three different areas of a particular asset’s performance. These three areas are: Availability, Efficiency, and Quality.

In practice, the three areas of performance interact according to the following OEE Formula:

OEE = Availability x Efficiency x Quality.

Differences between OEE formulas are found in the ways that each of these three factors are measured, so it is important to be precise in this regard.

At a high level it is helpful to think about and discuss OEE in specific ways. First, for example, OEE measures how often an asset is available when it should be producing product for a customer

Second, when an asset is producing finished materials for a customer, OEE measures how close the asset is producing at its theoretical maximum potential.

Third, for those products that are produced, OEE measures the percentage of products that are produced within quality specifications.

From among its industrial clients, LNS Research has been collecting critical data on people, process, metrics and technology. As of September 10th, 2012, we have benchmarked over 350 different companies across a number of different strategic objectives, metrics, and operational excellence capabilities.

Our goal is to benchmark over 1,000 companies by the end of the year and make this data available to our clients through an interactive, benchmark data web portal. Through this portal clients will be able to compare their performance to peers in metrics like OEE, On Time and Complete Shipments, Successful New Product Introductions, and Cost of Quality just to name a few.

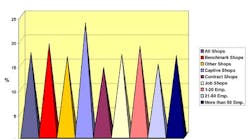

The above figure contains a deep set of rich data. It shows the distribution of performance in OEE across a number of different discrete manufacturing industries. If your company is active in the aircraft/defense sector, for example, or Automotive, Semiconductor, Electronics, Industrial Equipment, or Medical Devices, this analysis can be used to compare corporate performance against the median as well as top quartile performance in OEE.

However, we want to provide a forward look into the data prior to the full portal launch. As you conduct your own analysis, here are a few important observations to consider according to industrial sectors include:

Aerospace and Defense has the lowest median performance, but it also has a broad distribution with performance well above the median in the middle two quartiles. There is a lot of room for improvement on average, but also some impressive performance out of the top quartile.

The Semiconductor sector also has a low median, but a much tighter distribution. As an asset-intensive industry all companies could improve profits by improving asset utilization in OEE.

Automotive manufacturing is surprisingly low compared to all respondents as well as some of the other performers. There is also an impressive distribution of performers well into the top and bottom tails in performance. As with A&D, there is much room for improvement among some companies.

Electronics is dead even with the median for the overall population. However there are not a lot of companies performing at the median, but rather there are large groupings around 90% and 70%.

The Industrial Equipment sector is an OEE leader among manufacturing industry groups, and impressively out performs other discrete industries like A&D and Automotive. In this group, an impressive share of respondents are in the top two quartiles and are performing above 90%

Medical Device manufacturing is the real surprise of this analysis. Many people assume that because it is a highly regulated industry with high margins, its efficiency is low. Our analysis shows otherwise. More analysis is needed to determine why OEE performance is so strong among medical device manufacturers, but our guess is that it has to do with maturity around systems used to manage quality and change control. Companies in this manufacturing segment are at a severe competitive disadvantage if performance isn't well above the overall average.

We hope you find this data valuable from a benchmarking perspective, and we are looking forward to expanding our coverage in this area over time. If you plan to measure the OEE metric in your plant(s), or are just interested to learn more about how to measure this metric, I recommend you to read our research report on Taking Overall Equipment Effectiveness beyond the Plant Floor.

Matthew Littlefield is president and principal analyst for LNS Research based in Brookline, Massachusetts. LNS Research provides executives a platform for accessing unbiased research and benchmark data to improve business performance. Littlefield writes for the LNS Research blog where he covers topics including enterprise quality management software, manufacturing operations management, asset performance management, sustainability, and industrial automation 2.0.