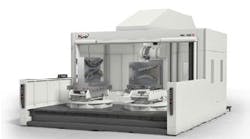

A machining center at Concept Components Inc. producing aerospace parts.

Jim McGuigan comes f rom a long line of machinists.

His grandfather had a machine shop with his father and uncle where Jim spent his early years sweeping floors on weekends.

Twenty years ago, when he was 23-years-old, he bought a Hardinge chucker lathe and struck off on his own. It was a modest turning shop, but he has made it grow.

Today, McGuigan has 27 CNC machines housed in 26,000 sq-ft. of a 30,000-sq.-ft. building he bought a year ago to consolidate his shop from three bits of rented space.

Concepts Components Co., McGuigan’s shop, has 26 employees who make precision parts for aircraft, microwave and other antennae, lasers, and Xray machines, for the military and for the textile industry among others.

McGuigan said he keeps his shop competitive by making parts faster than it did before.

|

“The plant manager logs in all jobs and locks in cycle times.

“Then, all jobs go into the computer for a cost analysis. The next time the job comes up, we know the cycle time, and we look at how we can use machining and tooling technology to maneuver it through the floor faster,” McGuigan said. Although he does the computer analysis, McGuigan doesn’t leave details alone.

Each day at Concept Components starts at 6 a.m., and at 7, he meets with his staff to review the work that’s going to be done. And, he walks the shop floor to check on progress.

“We have constant communication between us. That’s the key to getting it done the right way the first time you do it,” McGuigan said.

Besides getting the work done right the first time, McGuigan said he sees three factors that a shop needs to keep in mind to be competitive and thrive in business:

Capital investment.

Long-term retention of key employees.

And, customer service.

“Capital investment is the most important thing. We have an enormous investment plan,” McGuigan said.

Concept Components has grown substantially in 20 years, and McGuigan said he has put two new machines — and all of the support staff and tooling that is needed for them — on his floor each year for the past seven years. McGuigan and Concept Components is a confirmed Mazak shop. It counts six Mazak horizontal milling machines, and four machining cells populated by Mazak lathes among its 27 CNC machines.

The shop moved from a straight turning shop in its infancy to add screw machines and, later, its milling machines and machining cells.

McGuigan said having lines of Mazak machines makes his work easier because tooling, chucks, jaws, fixtures, programs and other tools all can be standardized.

“We have a standard portfolio of tooling and fixturing, and the new machines that can have 80 to 120 tools in their magazines make it easier on our guys because they don’ t have to look for tools,” McGuigan said.

That standard portfolio of tooling and fixtures is a critical component for the shop to establish the first-run cycle times that the plant manager tracks. When the job comes back, McGuigan looks at using special tools or machines to push the job through the shop faster. By knowing the performance of the standard tools and machines, the operations can be optimized with specials.

“As we develop jobs, we invest in better tooling to get the job done faster. We’ll look at special tooling to overcome long processes, and we try new tools all the time,” McGuigan said.

Concept Components cuts aluminum, 4130 steel, plastics and composites and, while it doesn’t typically work with exotic alloys or titanium, McGuigan said his shop can cut parts in 1045 steel as fast as it can cut parts in aluminum.

As for his employee relations, McGuigan said many of this people have been with the company for a long time, including both of his two shop foremen who have been with the 20-year-old company for 19 years. The shop works 50 hours to 55 hours a week on one staggered shift.

The shop pays full medical benefits, and provides vacation time and a 401K program with matching options. And, McGuigan said he never worries about paying overtime when it’s needed to get orders out to his customers.

On customers, McGuigan is unbending and has only one rule: “Whatever the customer wants is right.”

“It’s that simple. We try to do whatever we can to maintain the sense of security our customer have in us so that they’ll keep us on their team,” he said.

Concept Components has a diverse customer base, and McGuigan works to keep it that.

“I would rather have 50 $1,000 checks per week than one $50,000 check. We’ve always worked hand-inhand with our customers, and I think that one big customer can get to control you too easily,” he said.