Iscar's Jet-Cut system delivers coolant through the insert to the cutting edge.

Rouse-Arno Short-Cut insert holders have been redesigned for optimum clamping strength.

High temperatures at an insert's cutting edge shorten its life and contribute to reduced quality. Manufacturers have devised innovative techniques for delivering coolant just where it's needed — at the insert cutting edge.

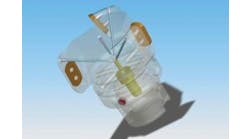

A new upgrade to Do-Grip parting inserts from Iscar Metals Inc. (www.iscarmetals.com) — the Jet-Cut system — features a coolant hole that passes through the insert to an outlet near the cutting edge. The DGNC inserts are designed for parting and grooving operations on stainless steel and high temperature alloys. When machining these materials, the temperature near the cutting edge can become very high, causing premature wear. Applying coolant to the cutting zone reduces these temperatures.

The Jet-Cut inserts are also good for grooving and parting applications where there is a problem getting coolant to the cutting edge. Sometimes, with traditional coolant-delivery methods, the way the chip exits the workpiece can prevent coolant from reaching the cutting edge. With DGNC inserts, coolant is delivered exactly where it needs to be while also cooling the insert internally. Iscar said the application of coolant through this system increases tool life and provides a smooth surface finish. In addition, materials such as titanium, Inconel, and austenitic stainless steel tend to strain harden during the cutting process producing long, tangled chips. By applying coolant through the Jet-Cut system, flank and cratering rates are reduced to substantially increasing tool life.

Coolant is supplied either directly to DGFH-C blades used on regular blocks, or through the SGTBU-C blocks that have coolant passages or connecting ports. Inserts are available in widths of 0.118 in. ( 3.0 mm) and 0.157 in. (3.99 mm) in C and J-type chipformers.

The Short-Cut-SIS internal grooving insert holders from H.B. Rouse & Co. (www.rouse-arno.com) are designed to maximize tool life by providing through-the-clamp coolant directed at the insert. The company said cutting performance is increased due to compact, stable and accurate insert positioning within the holder. Replaceable, high-positive geometry AM-geometry inserts, in conjunction with the new SIS holders, work for machining stainless steels, steels and cast steels with low cutting forces. The inserts produce medium to large chip cross sections in continuous or interrupted cuts even under unfavorable working conditions. The high positive cutting edges produce free cutting with good finishes and chip control with low horsepower.