Magnos magnetic workholding systems allow clamping of different workpieces without changing set up.

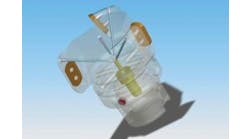

Magnos magnetic workholding from Schunk (www.schunkusa.com) uses electro-permanent magnets to clamp ferromagnetic parts. Square magnetic poles are arranged as north and south poles in a chessboard formation. The square poles are magnetically independent and consist of a steel core surrounded on four sides by nonreversible, permanent, neodymium magnets. Located below those magnets are reversible AlNiCo magnets.

The square geometry of the unit's magnetic poles creates a uniform clamping force. Schunk says reliable clamping is assured, even during rough machining, as a result of the high holding forces of the magnets. The magnets require only a brief period of time for electricity to activate and deactivate the magnetic field. Once activated, the power supply can be disconnected, but the clamping force is maintained.

Pole sizes of 50 mm (1.97 in.), 75 mm (2.95 in.) and 100 mm (3.94 in.) make it possible to customize Magnos units to individual applications. Additional magnetic pole extensions are available as accessories to improve workpiece location and to compensate for surface irregularities.

The company says large workpieces clamp better, because more clamping force is generated as additional magnetic poles are covered. Electropermanent magnetic chucks are best suited for workpieces thicker than 0.4 in. and larger than 10 in. by 10 in. That results in approximately 16 square poles of coverage.

Schunk says magnetic workholding offers several advantages including:

- A workpiece can be placed flat onto the Magnos magnetic chuck to allow tool access to five sides in one clamping.

- A workpiece is clamped within seconds and eliminates the need to adjust the clamping elements or to change the workpiece setup while it is being processed.

- The permanent magnet clamping force is applied uniformly across the entire workpiece minimizing vibrations while improving surface finishes and increasing precision.

- Thin walled or sensitive workpieces are gently clamped by the magnetic clamping force. Workpieces do not warp or twist, and are not crushed by forces applied at a point.

- The clamping system operates independently of the type of machine, does not require previous planning, and is not dependent on a technology system with specific system interfaces. Interventions in the machine program are not necessary.

- Workpieces of any structure can be clamped with the Magnos magnetic pole extensions. The movable (selfshimming) pole extensions adapt to workpiece contours so that workpieces are supported and rest solidy on the extensions.