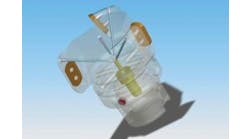

Sandvik Coromant's Coromant Capto Damped Milling Adaptor has an internal system that instantly damps vibrations.

The Coromant Capto Damped Milling Adaptor, recently introduced by Sandvik Coromant (www.coromant.sandvik.com/us), reduces vibration while milling with long overhangs. The product's sophisticated dampening mechanism eliminates any perceptible vibration caused by the cutting forces applied while endmilling or profile milling with overhangs up to seven times the coupling diameter. The adaptor comes standard with a Coromant Capto coupling in mounting sizes C4, C5 and C6, and in threaded coupling diameters M10, M12 and M16. The Capto Damped Milling Adaptor consists of a heavy tuning body, with a certain inertia mass, suspended in two rubber bushings or springs, one at each end of the tuning body. The tuning body is surrounded by a special oil. When machining, if variations in the cutting force cause the tuning bar to vibrate, the dampening system is activated immediately, and the movement energy of the bar is absorbed into the tuning system. When the tuning bar starts to vibrate, the damper mass inside the bar, which is suspended on rubber springs, also starts to vibrate.

Because of the damper oil, and internal damping in the rubber springs, vibration of the damping system is out-of-phase with the bar vibration. As a result, energy of the vibration is transformed to heat in the damping oil and the rubber elements, and vibrations are damped out. The company says the system reacts very quickly to machining vibrations, and the bar barely starts to vibrate before the vibration is stopped.

The Capto Damped Milling Adaptor is part of a family of antivibration tools, called Silent Tools, for internal turning, milling, boring and drilling. These products are damped to work on overhangs from 4 to 14 times the coupling diameter — beyond the limitations of solid steel and solid carbide shanks.

Sandvik Coromant offers tuned adaptors in different versions, such as Coromant Capto and HSK mountings, for both arbor mounting face and shoulder milling cutters and smaller shank cutters with threaded couplings.