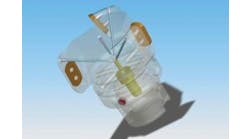

Romi Machine Tools Ltd. (www.romiusa.com) has introduced the Romicron fine-boring system that permits adjustments of 1 µm (0.00004 in.) on the tool radius without removing the tool from the machine. The system is for production applications that demand statistical process control with CpK of 1.33, or greater.

Romicron's marked graduated dial makes it easy to see each adjustment, and stops at each graduation allow operators to feel and hear (click) the adjustment. No wrenches are required for locking the tool. Through face-to-face contact, the Romicron KR coupling eases handling for assembly or disassembly to switch one head for another. With the KR coupling, the Romicron tool can be run in another machine by changing the appropriate adaptor.

The Romicron SVS system has 10 models with a boring range of 25 mm (0.984 in.) to 183 mm (7.205 in.) and offers through-the-tool coolant when coolant is available through the machine spindle. The SVU system, with three versions and a bore range of 10 mm (0.394 in.) to 326 mm (12.835 in.), is balanced to G 6.3 according to ISO standard 1940 by adjusting one dial.

SVUBB1/SVUBB2 boring heads use a number of replaceable boring bars for a boring range of 4.0 mm (0.157 in.) to 16.5 mm (0.649 in.) with SVUBB1 and 6 mm (0.236 in.) to 25.5 mm (1.004 in.) with SVUBB2. Both models are designed to be inexpensive solutions for serial applications and have the precision and functionality of other Romicron models. They are supplied prebalanced according to the diameter to be machined.