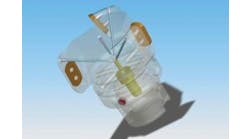

Coated round insert cutters from Seco Tools Inc. can handle copy milling operations for mold and die applications.

A new line of round insert cutters from Seco Tools Inc. (www.secotools.com) can be used for roughing and semifinishing in face and copy milling applications. The new cutters feature a hard nickel coating (700+ Vickers) on the cutter body that protects against chip wear, offers longer tool life and aids in chip evacuation.

Redesigned cutter bodies for the 10 mm, 12 mm and 16-mm diameter inserts have improved axial support in the pocket seat and provide a stronge rlock. The inserts have a round anvil shape and short anvil height to provide additional stability and allow for more cutting edges. This design change also ensures secure locking of the insert to prevent it from tilting and damaging the pocket seat.

The company said the cutters are strong and versatile enough to handle many applications including circular interpolation, helical interpolation ramping, side milling, slot milling, plunging and ramping. With a range of insert geometries, the new round cutters can handle light cutting to difficult machining in a variety of materials.

Selected cutters can also be supplied with high-density, vibration-damping shanks or the Combimaster connection.