Improving competitiveness in the face of price pressures and cost increases has historically been one of the chief concerns for American manufacturing businesses, along with improving revenue or throughput, and the lack of available skilled labor. Year in and year out surveys show this, and during my visits to machining businesses this has never been truer than it is today – due to inflation.

Machining businesses are feeling this pressure as much or more than consumers. If the cost increases incurred aren’t being passed along to your customers, your margin is being compressed, which of course impacts your competitiveness as well as longer term objectives like investing profits in new equipment, technology and other business needs.

The question becomes: If it’s a forgone conclusion that you’ll pay more for most things you buy, how can you achieve lower costs so that your profitability returns to satisfactory levels? Is it possible you can emerge even more profitable than you were prior to the onset of inflation?

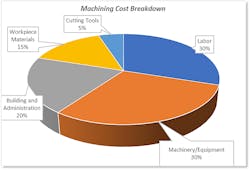

Reflecting on the foundational costs of machining will guide us where to focus. Generally accepted machining cost allocation is as follows:Let’s start with the lowest cost percentage – cutting tools.

Cutting tools make up only 5% of the overall manufacturing costs, and cutting tools have been just as susceptible to inflation as those overall costs. It’s unlikely you can buy your tools less expensively today than was possible a couple years ago. As a matter of fact, even if you somehow were able to buy them 10% cheaper today, the impact on shop profitability only improves by a half a percent.

Your workpiece material typically isn’t an area where you’d derive significant savings versus your competitors, as the market demand and current material price position and order quantity normally dictates those prices. The remainder of the costs, by and large, are fixed. Your building and overhead, your equipment and your labor are essentially stable and don’t fluctuate.

It’s the productivity of your equipment and your people that can drive real cost savings. Although the labor rate and machinery costs are fixed, their productivity and output are not. These two components make up approximately 60% of the cost of machining a part, so improving productivity here should move the needle, right?

Let’s take a closer look and use material removal rate (MRR) as an example. Measured in cubic inches per minute, MRR is a significant factor in making more parts faster. The possibility of doubling or tripling productivity is achievable, particularly in milling. In the past several years, the MSC MillMax® service has averaged over 200% improvement in milling MRR.

Here’s a milling example where the following points are true:

• Current Profit margin is 15%.

• The rough milling cycle is 20% of the entire machining/manufacturing time.

• The current material removal rate in Titanium is 2.00” cubic inches per minute.

Improving the MRR of this specific operation by 100%, or moving from 2 to 4 cubic inches per minute would improve the profit margin by at least 300 basis points, or 3%. That’s if you consider only the machine productivity. What about the employee productivity, which is as important as cost per piece? Along with shorter cycle times comes more parts made per hour or shift, etc. This very same MRR improvement can further reduce the cost per part through more productive labor, improving profits even more on a per part basis.

This same philosophy and action can be replicated for a wide variety of applications and operations. Set-up reductions due to quick-change solutions, advancements in drilling, automated deburring, turning, and part-off are just a few of many opportunities that can be reviewed and possibly improved by operating at greater speeds.

The ability to generate improved profits, even in times of inflation, can be found with your equipment. Responsible speed improvements can do wonders for a shop. If time is money, then less time is less money. Challenge what you’re getting out of your equipment and your tools. Use innovation and new technology to your advantage. When you do, you’ll find your operations are more profitable, you’ll have more capacity (increased revenue opportunities) and improved productivity.

Jamie Goettler is the Senior Director of Metalworking Sales and Innovation with MSC Industrial Supply Co.

To find out more about how new technology can support your goals for 2023, contact the MSC Industrial Supply Co. innovations team.