Product-performance demands now require that machined parts adhere to very tight specifications. At the same time, parts with complex geometries, odd or awkward shapes, and internal blind spots are common now, and customer quality requirements for finished parts remains high.

Cleaning these challenging parts can be difficult. Production debris like machining, stamping, or cooling oils, dust, metal filings, marking inks, fingerprints, and other "soils" must be removed prior to processing or assembly. It is essential that parts are clean and dry before commencing finishing operations like anodizing, plating, painting, or welding.

Many finished parts are held to high cleanliness standards and often are inspected under black light, particle count, water break, or other analysis, to ensure they meet the customer's requirements. However, as the parts get smaller and more complex, it is trickier to clean them quickly, efficiently, and without damaging the substrate.

Vapor degreasing — Vapor degreasing machines are a common way to clean metal parts because they provide consistent cleaning and are highly effective at removing lubricants, silicones, and greases. Vapor degreasing is fast, efficient, has a high throughput and is easily automated into standard production lines. Parts emerge from the vapor degreaser cool, dry, and ready for processing or packaging. The systems use no water and little electricity, so it is a sustainable way to get parts clean.

Most modern cleaning fluids are a mixture of compounds that may include hydrocarbons like mineral spirits, isopropanol, and ethanol. How these compounds are combined will determine the cleaning fluid’s effectiveness and its material compatibility. The vapor degreaser can use just one type of cleaning fluid or it can be mixed, blended, or custom formulated to remove a specific soil from a specific substrate, maximizing cleaning effectiveness.

Soiled parts are immersed in the continuously filtered and distilled cleaning fluid inside the vapor degreaser to dissolve or lift the soils from the parts' surface. In some instances, ultrasonic agitation is added for additional cleaning muscle.

As the parts are lifted from the cleaning fluid, they undergo a brief vapor rinse and drying process. The cleaning fluid condenses and drips back into the vapor degreaser to be reused. The vapor degreaser recycles and reuses the cleaning fluid hundreds of times before it needs to be refreshed or replaced. This helps reduce the cost of hazardous waste removal. After a typical cleaning cycle of about 6-20 minutes, the parts come out clean, rinsed, dried, and ready for the next stage of production.

Today, there are a number of good cleaning fluids on the market for cleaning metal parts inside a vapor degreaser. Each has particular strengths, weaknesses, and subtle nuances. However, there are nine characteristics that typically make up a good cleaning fluid.

1. Nonflammable. Nonflammable cleaning fluids are safer for handling and storage. Plus, they do not require specialty fire or explosion-proof equipment. Most vapor degreasers are engineered to use nonflammable cleaning fluids.

2. Maintenance-free. Cleaning fluids should remain stable when exposed to moisture or water. In addition, they should not require acid-acceptance testing, stabilizer maintenance, or lab analysis.

3. Low boiling. Low boiling cleaning fluids (below 100°C) will clean parts thoroughly but still allow the vapor degreaser to run more efficiently, saving energy costs. Plus, using the lowest-possible boiling temperature allows cleaning of plastic or delicate parts without damage.

4. Low surface tension. Low surface tension of the cleaning fluid allows it to wet all parts' surfaces and work its way into small clearances.

5. Low viscosity. Low-viscosity cleaning fluids will reach into, and even more importantly, evacuate from tight crevices within parts. Most metal cleaning fluids are more viscous than water, the better to permeate complex shapes and tiny parts.

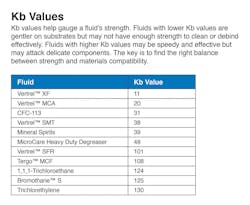

6. High density.Modern cleaning fluids are typically20-30% heavier than water, and over 50% heavier than alcohol. High-density cleaning fluids are good for use on particulates such as metal shavings or polishing pastes that cannot be dissolved. Instead, the particulate is displaced or lifted off the components. Then, the high-density fluid pushes the particulate off the surface.7. Correct solvency or strength. Cleaning fluid strengths are typically indicated by a Kb value. Kb values typically range from very mild (10) to very strong (greater than 125.) The cleaning fluid should have a high enough Kb value and solubility parameter to hold and dissolve a high concentration of the soils, yet not damage any of the parts materials.

8. Low toxicity. To protect workers and the environment, the cleaning fluid should not contain n-propyl bromide (nPB), methyl pyrrolidone, perchloroethylene (Perc) or trichloroethylene (TCE), all of which carry health and or environmental baggage.

Users should refer to the fluid’s SDS to check the cleaning fluids exposure PEL, or Permissible Exposure Limits. Outlined by the EPA, higher PEL ratings are better. For instance, nPB is rated at just 0.1 parts per million while TCE is rated at 100 parts per million. However, modern metal cleaning fluids have typical PEL ratings of 200-250, making them significantly better for the safety of exposed workers.

9. Environmentally sustainable. Many new metal-cleaning fluids feature new formulations that offer excellent performance along with improved environmental properties. Unlike older cleaners that caused air and groundwater quality concerns, the new cleaning fluids have a very low Global Warming Potential (GWP), which helps reduce greenhouse gas effects and low Ozone Depleting Potential (ODP) content to meet strict regional air-quality regulations.

The right metal cleaning fluid — Many machine shops and metal fabricators are processing innovative parts designs and implementing advanced manufacturing processes. However, even state-of-the-art companies can benefit from upgrades to their cleaning methodology.

A vapor-degreasing machine is an effective, reliable, and repeatable method for successful metal parts cleaning. Parts are cleaned, rinsed, and dried in a single machine using modern cleaning fluids that are replacing the older, environmentally questionable legacy solvents. These next-generation cleaning fluids offer many benefits, including better cleaning outcomes and lower toxicity profiles.

For companies looking for help selecting and using sustainable metal cleaning fluids, it is essential to work with a partner that has metal parts cleaning fluid and vapor degreasing expertise. A cleaning partner can help conduct on-site audits or perform in-lab tests with sample parts to ensure cleaning success. Based on specific parts' make-up and the contamination encountered, they can recommend, or formulate, the fluids and metal cleaning methods that will work best.

Venesia Hurtubise is a technical chemist at MicroCare Corporation, a developer of precision cleaning solutions. She researches, develops, and tests cleaning-related products used in precision cleaning and medical applications.