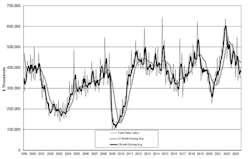

U.S. machine shops and other manufacturers’ new orders for capital equipment totaled $404.2 million during August, +16.1% more than during July but -12.2% less than the total for August 2022. The eight-month total for 2023 new orders is now $2.23 billion, according to AMT – the Assn. for Manufacturing Technology’s monthly USMTO report, which is a -12.6% decline from the comparable total for 2022.

The monthly U.S. Manufacturing Technology Orders (USMTO) report tracks orders for metal cutting and metal forming/fabricating machinery as an index to future manufacturing activity, as machining operations anticipate their upcoming business needs. The report summarizes order values nationwide and for six U.S. regions.

The month-to-month rise revealed some signs of strength in the manufacturing sector. "We are seeing industries focused on shorter-term projects reduce their spending, but at the same time, OEMs focused on longer-term production timelines have been increasing their spending, keeping orders at an elevated level," AMT president Douglas K. Woods reported.

An example of rising OEM orders offered by AMT is the volume of demand from automotive transmission manufacturers, whose three-month streak of orders are the highest since June to August 2017.Manufacturers of engines, turbines, and other power transmission technologies are also increasing orders, according to AMT, and the rate of increase is the largest sustained increase in orders since summer 2008. At that time, the increased demand was attributed to power plants transitioning from coal-fired operations to natural gas turbines.

"The net result is that for the third consecutive month, the gap between year-to-date orders in 2022 and 2023 has narrowed, falling from a 14.6% deficit in May to the 12.6% difference we see today," Woods added

The August report showed strong results for metal-cutting machine orders in five of the six regions (in the North Central-West, the order total fell -16.2%), though only the Northeast (+10.4%) and Southeast (+2.7%) showed any year-over-year increase. The YTD order totals are in decline across all regions.

New orders from job shops during August were “well below their historical trend despite their share of unit orders remaining elevated,” AMT reported. “This indicates that while job shops are continuing to buy to increase capacity, OEMs are increasing their purchases of specialized machinery to make more complex, higher-value parts.”

Woods offered that currently, the increases in demand for new machine tools is rooted in consumer demand. "To gauge the probable path of manufacturing technology orders in the future, we should keep an eye on the health of consumer spending," he said.

"Between mortgage payments becoming a larger share of discretionary income, wages in many industries not keeping pace with inflation, and ongoing labor disputes shuttering production lines, there are still several headwinds that face both consumers and the manufacturing technology industry."