KREBS & RIEDEL introduced new premium grinding wheels with high process reliability for large gear grinding.

In recent years, wind power has been an important factor in reducing CO2 emissions. Wind turbines are getting bigger and more powerful, while production costs have to be reduced. This requires production methods that can produce the gears cost-effectively and in high quality, even with complex flank modifications. Gear sizes for wind power typically range from 800 to 4000 mm. Some gears can reach a diameter of 8000 mm and weigh up to 100 metric tons. The most common size in the field of external gears is 1200 mm in diameter and ranges from module 12 to module 52. The profile grinding wheels typically have a diameter of 100 - 450 mm.

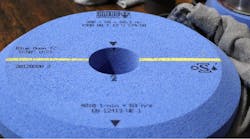

To achieve maximum synergy between the grinding machine and the grinding wheel, Krebs & Riedel optimizes the process with onsite application support, and offers with the Blue Moon™ TZ, a new premium grinding wheel with a precision-shaped abrasive grain.

Blue Moon™ TZ is characterized by a very high cutting performance and a very high material removal rate. "In some trials, the material removal rate (Q'w) was more than 30 mm³/mms," said Sigurd De Ridder, at Krebs & Riedel senior application engineer, who conducts trials and process optimization for customers worldwide. He said: "Precision-shaped abrasive grains are state of the art today. Blue Moon™ TZ is comparable in performance to other precision-shaped abrasive gains on the market. It is self-sharpening, very sharp-edged, microcrystalline and has an elongated trapezoidal shape."

The homogeneous pore structure of Blue Moon™ TZ contributes to an extreme improvement of the entire cooling system during the grinding process. Due to the open structure, the entire grinding wheel is immediately flooded by the cooling liquid. Even with extreme material removal rate, the chip is transported away from the contact surface. This avoids heat input that could lead to thermal damage to the gear.

Learn more at www.krebs-riedel.com