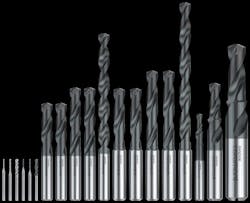

New Drill Series for Multi-Material Applications

SANDVIK COROMANT introduced the CoroDrill® Dura 462 drilling family with more than 2,000 assorted sizes for different materials and applications. With new, advanced coating technology, extended tool life, and easy accessibility, the CoroDrill Dura 462 is an ideal solution for multi-material drilling.

By combining versatility and precision, CoroDrill Dura 462 eliminates the need for separate specialized tools for different materials.

The point geometry of the CoroDrill Dura 462 drilling family is designed for adaptability, delivering positional accuracy and improved tool life across a wide range of materials, component sizes and shapes. With consistent machining performance from a single tool, users can consolidate their tool inventory to streamline operations and still achieve optimal results.

CoroDrill Dura 462 features a large range of sizes, ensuring an ideal fit for virtually any drilling application. From micro drills starting at 0.030 mm with a drill depth up to 6xDC, to larger variants up to 20 mm and a drill depth of up to 8xDC, this assortment allows manufacturers to tackle a wide array of materials and machining conditions.

All standard size drills, starting from 3 mm, are fully coated using new Zertivo 2.0 technology to create a multi-layer PVD coating.

“The Zertivo 2.0 coating technology is a standout feature of CoroDrill Dura 462, delivering significantly longer tool life by reducing wear and improving heat resistance,” stated James Thorpe, global product manager for hole making and composite machining. “This coating enables faster cutting speeds without compromising performance, which ultimately results in higher productivity and reduced cost-per-hole.”

CoroDrill Dura 462 has already been shown to improve efficiency across different applications in early tests.

“One customer using CoroDrill Dura 462 for blind hole drilling saw an 85% increase in productivity with a tool life of more than double that of a competing tool,” according to product application expert Matthew Johnson. “Another customer, seeking to improve cost-efficiency while safeguarding process security in cross-hole drilling, experienced a productivity increase of 110% and a 36% extension in tool life compared to their previous solution. With substantial improvements in both performance and tool life, CoroDrill Dura 462 is a game changer for multi-material drilling.”

CoroDrill Dura 462 is also applicable for services such as reconditioning and recycling.

“We’re committed to supporting our customers throughout the tool lifecycle,” Thorpe said. “Prolonging tool life and recycling used tools benefits both our customers and the environment, making our solutions an investment in the future."

Learn more at www.Sandvik.Coromant.com