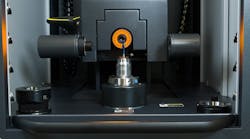

ZOLLER introduced significant improvements to its “genius” universal tool measuring machine for cutting-tool manufacturers and end users. Applications range from incoming inspection, in-house regrinding, research, benchmarking, wear analysis, tool setup, in-process control, final inspection to cutting tool certification and reverse engineering.

Meticulous and comprehensive inspection is important to help manufacturers maintain the most complex of tool geometries and ensure design integrity across the entire manufacturing process.

From the rapid testing of individual criteria to complete, fully automatic, operator-independent checks, tools are inspected quickly, simply and precisely. The measurement results are documented in detail and can be transferred easily to grinding machines at the push of a button. As a result, the “genius”, saves companies valuable time during work preparation and programming.

The main feature improvements include:

- The FEM designed machine base has been made stiffer and heavier to allow for increased speeds AND increased accuracy, while simultaneously reducing vibration.

- A new machine control cabinet houses the IPC, PLC and pneumatics. The solution removes any heat source from the machine base and provides easy access.

- A vertically actuated cabin door with an ergonomic handle has also been added to improve day to day operating conditions.

- Inside the machine the operator finds smartly integrated pockets for collets and spindle adapters.

- Further, the proven one-hand operating device and the integrated membrane keypad have been ergonomically optimized.

- Two 5-megapixel 2D transmitted light cameras have been added for special applications. One with increased pixel density to capture very small contours. The other with a very large field of view to dramatically reduce scanning time for form tools.

- User-specific widgets in the new and refreshed “pilot 4.0” software platform.

With “pilot 4.0”, users are quickly equipped to run any measurement and inspection program for any requirement, including typical tool measurements of helix angles, radial reliefs, lands, gash angles, head lengths, center offsets, chamfer heights and end face facets to list but a few.

Offline programming is available through Zoller “CAZ”. The platform resembles a full functional virtual measuring machine. Tools are imported as 3D STL or STP files.

Learn more at www.zoller-usa.com