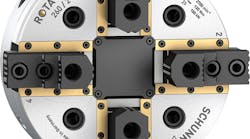

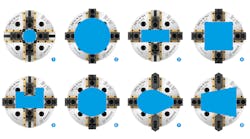

SCHUNK’s ROTA-M flex 2+2 is a low-maintenance 2+2 chuck jaw specially designed for meeting the increasing demands of the market. The patent-pending compensating mechanism provides a very long compensation stroke: Depending on the size, it amounts to 5.1 up to 10 mm per jaw. This means increased flexibility for clampable workpiece geometries and a wide variety of possible applications. In many cases, a single ROTA-M flex 2+2 chuck will be sufficient for covering a wide range of part geometries.

Special seals on the guideways prevent grease from washing out under coolant pressure and gradual loss of clamping force. Even in the case of low clamping forces, the precise functioning of the chuck is ensured. At the same time, the sealings protect the chuck body against chips and dirt, process safety increases and maintenance intervals are extended.

As of size 800, users benefit from the weight-reduced design. The chuck face is equipped with grooves and fixed stops allow the chuck to also be used as a vise. Moreover, the large sizes are designed for use on vertical lathes. The SCHUNK ROTA-M flex 2+2 is equipped with a flexible serration (1.5 mm x 60° or 1/16“x 90°). Learn more at www.schunk.com

For more new products, visit newequipment.com