Every micrometer counts when it comes to honing of high-precision components, such as those required for injection or hydraulic applications. To meet those high quality standards, honing machine manufacturer Kadia Produktion GmbH + Co. applies direct-drive technology for the spindles and the stroke. Meanwhile, it has introduced the second generation of its LH honing spindles.

Kadia introduced the first Lean High-speed (LH) honing spindles in 20014, offering direct drives for rotation and stroke. These were a genuine innovation, and the developer immediately patented its concept worldwide.

“The direct-drive technology is unbeatable in terms of smooth operation and control behavior’s precision,” according to managing director Henning Klein. “Its use in the small- to medium-diameter range – this is our specialty – has led to a leap in productivity and quality, which is rarely the case with new developments nowadays.”

It is the first application of a direct drive for the stroke movement via linear motor, and it offers an optimally adapted drive and dynamic performance, both of which are prerequisites for high material removal rates.

Moreover, the linear motor works contact-free, even “wear-free” according to Kadia, and transfers practically no vibrations to the honing tool. By contrast, the conventional honing stroke systems rely on components that are subject to wear, such as ball bearing spindles. The deceleration and acceleration in the reversal points of the oscillation quickly impose limits to the constantly high precision.

Similar advantages are featured by the spindle drive, a direct-drive synchronous built-in motor. The low-maintenance motor spindle transfers high torque without causing the tool to vibrate. Tool expansion takes place electromechanically by means of a high-resolution servomotor with precision screw drive. On the honing stones, its possible to set feed rates in the nano range.

Kadia combined all these components into one particularly compact unit: The spindle motor and the expansion motor are arranged coaxially, one above the other, and in the immediate vicinity of the linear drive. The directly initiated expansion movement of this arrangement increases the rigidity of the entire system.

The concept is completed by an inner coolant supply, which provides optimal process cooling. “Due to our LH honing spindles, even demanding high-precision applications, such as match honing with clearance tolerances <1 µm can be safely implemented,” according to Klein.

Over nearly ten years, more than 700 first-generation spindles were supplied, in five variants, which are in reliable services for reliably in a wide range of single- and multi-spindle machines of the customers.

Ten years ago, machining system designers surely would have excluded the possibility of achieving a more compact design, but the progress has continued. “Many experiences have converged in the meantime,” Klein explained. “The individual parts and components as well as the applications have continued to develop. It was therefore time to adapt the successful concept to the current state of technology.”

For example, Kadia indicated the original concept offered room for improvement in the inner coolant supply, and this enabled a shorter design and a more comfortable accessibility for maintenance purposes. Tool clamping also showed potential for optimization: the customized hydraulic expansion chuck now seats directly in the honing spindle, not on the spindle tip. This affects not only the construction length, but it leads especially to an “ultra-precise radial spindle run-out.”

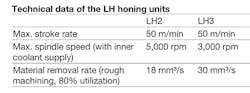

The most important improvement has been made to the overall design of the individual drives, in terms of performance, size, and weight, so that every honing spindle has now the best possible configuration. Another consequence of this is that the initial series of five variants has been reduced to two (designated LH2 and LH3), however, several variants are possible for the stroke and different standard lengths are available.

According to Kadia’s experts, despite the smaller size and weight reduction of almost 30%, LH2 achieves the same forces and torques as the previous KADIA standard spindle. The larger LH3 lies in the range of the formerly most powerful predecessor model at nearly 20% less weight.

“Due to the even more compact design, the dynamic range and the chip removal capacity have increased further,” Klein said. “The power consumption is now lower at the same time – an advantage not to be underestimated,” said Klein.

So, the new-generation spindle also impresses with its energy efficiency, notably because of the possibility of feeding electricity back to the grid. For example, the power consumption of an LH2 spindle during a typical honing process is 0.0025 KWh/workpiece. Along with a five-year warranty on the linear stroke drive offered by Kadia, this represents above-average value as well as high reliability.

A significant manufacturer of fuel-injection pumps deploys a Kadia T line honing machine equipped with five LH spindles for the critical step of the process: final processing of high pressure bores. Because of the narrow tolerances of a few µm, the components are “match honed.”

For that step, the previously manufactured pistons are measured in several measuring planes, and the results serve as target dimensions for the honing machine. The process flow is stored in the machine control system and is thus highly automated, so that handling costs are reduced towards zero.

The new LH2 shows what it can accomplish in this challenging application – match honing is said to be the supreme honing discipline. “Compared to the previous state of the art, the geometrical precision of the bore has improved by 5-10% and the matching clearance tolerance even by 50%,” Kadia’s managing director Klein concluded. “In his overall evaluation, the user confirmed a process quality increase of 25%… a giant leap forward.”