Toolholding and workholding technologies require just as much insight and innovation in development and design as the most powerful machining and turning tools, and Exsys Tool Inc. will be demonstrating a range of its own innovations at IMTS, including quick-change systems, compact designs, and modular adapters. Also highlighted will be comprehensive repair and rebuilding services for CNC turning center tooling products.

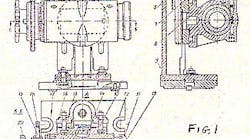

The Exsys Preci-Flex modular quick-change tooling system includes a selection of adapters engineered to hold different cutting tool and shank designs. The adapters’ common connecting feature locks into a standard base unit on the machine turret, so tool/adapter assemblies can be preset offline and then quickly switched in and out of the base unit. Tool positions repeat within +/-3 µm, eliminating the need to re-center, touch off, or make test cuts.

The Preci-Flex conical and flat-face planar interface duplicates the taper of the standard ER collet, so that ER collets can be used along with Preci-Flex adapters (though, at lesser repeatability) to mount collets, endmill holders, expanding collet chucks, and shrink fit tooling on a single base holder. Operated at the front face of the turret, the connector provides two tons of clamping force, and its compact design maximizes torque transmission and rigidity, increasing accuracy and productivity.

Another example of advanced modular quick-change tooling technology are the compact Eppinger C3, C4 and C5 connection base holders, which speed up and simplify tool changes. They also require minimal space within a machine tool, so they handle larger workpieces easily.

For Swiss automatic machine tools, Exsys Tool will exhibit Deco-Flex adapters, which have minimal envelope dimensions so they can increase manufacturing flexibility in a Swiss machine environment. The compactness also enhances rigidity, boosting machining efficiency.

The Deco-Flex connection has a conical and flat-face planar interface that ensures concentricity and repeatability. The system also offers specific adapters that combine with fixed and/or rotary tool holders to optimize tool performance and flexibility. Tools can be preset off the machine, allowing adapter/tool changes to be completed in seconds and thereby reduce setup times while increasing machine uptime.

Among its workholding technologies, Exsys will present three workpiece clamping systems from Gressel:

• Gripos modular machine vises clamp by tension rather than compression, producing no deflection of the vise baseplate, and are gradually and precisely adjustable from 10 to 100% gripping force. Turning a lever 160° provides mechanical amplification with complete clamping in less than a second, minimizing set-up times;

• Grepos 5-axis power vises feature the same actuation technology as Gripos vises and provide force amplification from 0-40 kN direct on the workpiece. The design of the vise permits access to the both sides as well as the underside of a part, facilitating true five-axis complete/simultaneous machining.

• Solinos modular single-clamping vises for small workpieces have interchangeable jaws and are offered in mechanical or hydraulic versions, providing clamping force up to 20 kN. Clamping range is adjustable without jaw removal, so it’s possible to complete quick changeovers between different parts. The vises can be directly integrated into pallets.

Exsys also will highlight its Exsys Tool Repair LLC. service that specializes in rebuilding driven tooling for CNC turning centers. Exsys is factory authorized to service Eppinger tooling and also is fully capable of repairing or rebuilding virtually every make and model of driven tools to OEM specifications.