BobCAD-CAM Inc. released Version 28 of its CAD/CAM software, a platform it describes as “powerful and affordable” for manufacturers designing prototypes or machining customized or high-volume parts. The software uses solid model designs to create toolpaths and NC g-code, for milling, routing, turning, or mill-turn machining; and plasma, laser, or waterjet cutting; as well as wire EDM machinining.

“We spent a lot of time talking with clients and getting feedback on what was needed and where we could improve,” according to BobCAD-CAM’s development executive Greg Myers. “I’m happy to say we were able to roll out a lot of those key features and upgrades with v28. I’m also thrilled to launch our brand new Mill Turn module, which we’ve been developing for some time now.”

Version 28 builds on three decades of CAD-CAM design and programming by the developer, which has included a CAD design system, an easy-to-use, “wizard driven interface,” Dynamic Machining Strategies™, 2- to 5-axis high-speed adaptive toolpath capabilities, and realistic simulations.

It said the new version offers improved drawing control in the CAD mode; custom tool shapes for milling tools; upgrades to the hole drilling system; new tabbing options; enhanced wrapped toolpath capabilities; and a new simulation interface.

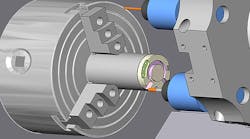

The new programming option to introduce customized and specialty milling tools adds to the software’s existing option for users to define and simulate custom-shaped lathe tools and inserts. With the new release, BobCAD-CAM fully supports the use of any custom and specialty shaped tools for CNC mill and lathe machine simulations.

BobCAD-CAM’s new Mill Turn module was designed to support increasingly popular multitasking machine configurations, and can support complex setups that can include multiple turrets, multiple spindles, programmable tailstocks and steady rests, and machines with B- (5-axis) milling heads, C-, and CY-axis capabilities.

The Mill Turn module supports nearly all mill/turn, multitasking, and live-C machine configurations. The C-axis milling capabilities of Mill Turn support the positioning and contouring motion on the outside diameter and part face, which can be used with indexing, wrapping, and rotary toolpaths to drill holes, cut pockets, and more along the part’s center line.

Y-axis milling support gives the user the ability to perform milling operations, both on and off the part’s center line, allowing for 2-, 3-, and 4-axis milling, and cross drilling on the outside diameter and part face.

B-axis, or 5-axis, milling head programming can be used with single-spindle and sub-spindle machine setups to provide the flexibility to best target the part when performing facing, pocketing, and hole drilling operations on complex part models.

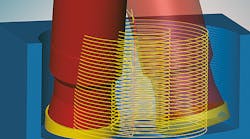

The new module offers a full machine simulation that works with users’ machine kinematics to provide an accurate representation of the complete part machining process with cycle time calculations, collision detections, and machined part deviations.

Also included is MDI programming capabilities, so machine programmers can set up a sequence of actions to be performed by the mill/turn machine. These event sequences can include actions performed before tool changes, after tool changes, or after an operation is completed.