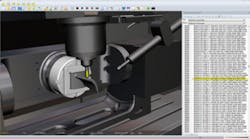

The GibbsCAM 2015 platform for production machining has debuted, bringing what the developer calls a “comprehensive update,” including a new Universal Kinematic Machine (UKM) engine that simplifies the task of CNC programming. The new version also extends the capabilities of previously available functions, and accommodates new machines of any configuration.

GibbsCAM is a product of 3D Systems, which took over Cimatron Ltd. late last year. Being a developer of “digital design and fabrication solutions” (including 3D printers, print materials, and cloud-sourced custom parts), 3DS portrays GibbsCAM as one element of its “design-to-manufacturing digital thread, facilitating cross-technology manufacturing between additive and subtractive methods.”

“With the new release of GibbsCAM 2015 we enable our customers to program any machine with a single program and a single interface,” according Ilan Erez, v.p./co-COO/CFO, Software Products. “The new features and enhancements in GibbsCAM 2015 are designed to save time in programming, provide more flexibility in selecting and using tools, and make toolpath verification and machine simulation more accurate and efficient.”

Among the new-release highlights are new tooling functions that let a programmer define, use, and simulate tools with icons, and dynamic 3D viewing of tools and tool holders. GibbsCAM 2015 supports straight, tapered and stepped shanks on all mill tools now, and new mill and lathe tool types have been introduced, including 3D form tools and 75° Diamond (ISO E-style) lathe tools.

GibbsCAM 2015 adds functions for executing holemaking steps from CAD, and full associativity for hole features from Autodesk Inventor, CATIA v5, Solid Edge and SolidWorks. Related, a new makes it possible for programmers to “edit” hole features, including compound holes, which are supported with multiple straight, tapered and threaded segments.

Hole feature recognition has been enhanced, and the five-axis drilling interface has been streamlined. These features make programming faster and simplify hole-making operations.

The new release provides “intermediate tooling support” for multi-task machining (MTM), which the developer stated makes tooling more manageable, simulation more accurate, and programming easier, with more accurate placement and orientation of tools.

Newly added functions include a tool block library and support for tool blocks, such as adapter blocks, holders for tool holders, right-angle and adjustable heads, and flash tooling. A fixture library and support for fixtures (chucks, tailstocks, steady rests and other work holding devices) are included.

According to 3DS, GibbsCAM 2015 has improved machine simulation as a result of UKM, intermediate tooling support, and an improved rendering palette. Rendering is more accurate and efficient, displaying intermediate tooling for a more complete simulation of all moving components.

Customized monitoring of critical conditions is possible with GibbsCAM 2015’s new Stops and Watches feature.

Finally, the new release is integrated with Sandvik Coromant’s Adveon Tool Library, so it’s possible to import tools from Sandvik and ISO 13399-compliant systems to make a standard library available at any time.

GibbsCAM is designed for programmers and machinists working with solid modeling, 2- through 5-axis milling, high-speed machining, mill/turn, Swiss machining, multi-task machining and wire-EDM capabilities.

“We are committed to providing 3D digital design and fabrication solutions that enable our customers to be more productive and competitive,” said Erez. “With the recent addition of GibbsCAM to the 3DS digital manufacturing thread portfolio, our customers can now enjoy the ability to use both subtractive and additive manufacturing to achieve the highest productivity possible.”