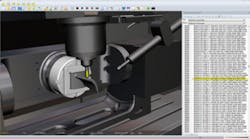

Geometric recently launched the 2014 version of its CAMWorks CNC program, noting that the addition of true G-code simulation makes it a complete CAD/CAM solution, integrated with initial part design functions and available for every step from writing CNC programs to full machine simulation. This functional flexibility, the developer emphasized, reduces data redundancy and saves production time on the shop floor.

CAMWorks is a parametric, “solids-based” CNC software system that emphasizes speed for programming and production. The developer claims CAMWorks reduces programming time significantly by using patented Feature Recognition technology in conjunction with “toolpath to solid-model associativity” and knowledge-based machining.

Geometric emphasized that accelerated programming with CAMWorks still allows programmers to execute efficient toolpaths, thanks to the CAMWorks VoluMill, to reduce cycle times and maintain competitive production standards.

Compatible with SolidWorks 2014 CAD programming, Geometric stated that CAMWorks 2014 accelerates design-to-part time and improves CNC programmers’ productivity with several program enhancements. Among these, it listed:

Enhanced turn feature definitions.Turn profiles are fully associated with the model from which they are extracted, making them fully associative to the sketches. This is “a first” in feature-based machining, according to Geometric, and makes changes in the CAM program quick and efficient.

Another addition to the new version, particularly beneficial to mill-turn operations, is the option to select turn profiles by specifying the angle at which the profile has to be extracted.

Effective toolpath review.Tool vectors for the toolpaths can be viewed during step-through simulation, making it easier to review five-axis toolpaths. Also, users can use a WIP (Work in Process) model as a start-up stock, when simulating sections of a toolpath, shortening the review time.

Increased automation in CNC programming.CAMWorks 2014 adds 39 APIs to the current suite that can help to reduce repetitive activity, and provide a foundation for users who want to customize or automate their systems to accelerate CNC programming output.

Simplified sub-spindle operations.The new version has greater flexibility in the sub-spindle operations thanks to the addition of more pre-programmed routines that are configurable to users’ needs.

CAMWorks also introduced CAMWorksView, a free 3D CAM data viewer app for iPad/iPhone/iPod users to view, review, and annotate 3D work-in-process (WIP) models and assemblies, toolpaths, and relevant operation data anywhere from the shop floor to the design room, without need for an additional CAMWorks license.

In addition, CAMWorks 2014 now provides Mori-APT CL code for the DMG Mori Seiki NMV, NH(X), NV(X), NL(X), and NT Series milling, turning, and mill-turn machines. The APT-CL code from CAMWorks is certified to drive these machines using the Manufacturing Suite Post Processor, eliminating the need for custom post-processors.

This approach provides CAMWorks subscribers with a complete solution that ensures that they will be operating their machines as quickly possible.

Geometric also enhanced its video instructions set as a useful reference guide for self-paced learning, to supplement training.