Gibbs and Associates reports that its GibbsCAM software is optimized for machining parts designed in SolidWorks®, developments that it introduced at the recent SolidWorks World 2013 Conference. Steve Aughinbaugh, an applications engineer for the CAM software developer made a presentation at that event, “Machining SolidWorks Features,” emphasizing the program’s simplification of machining solids created in SolidWorks. Aughinbaugh demonstrated how GibbsCAM uses “knowledge-based machining” to read SolidWorks part features automatically, and machine them with just a mouse click.

The GibbsCAM product line supports 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining and wire-EDM. It also provides fully integrated manufacturing modeling capabilities that include 2D, 2.5D, 3D wireframe, surface, and solid modeling. It is compatible with Windows 7 and certified for Windows Vista, and GibbsCAM’s data exchange capabilities are able to access the broadest range of native and industry standard CAD data formats.

In addition to being a SolidWorks Certified CAM product, GibbsCAM is certified under the Autodesk Inventor Certified Program; and is a Siemens Solution Partner Program-PLM for Solid Edge product.

GibbsCAM has numerous new capabilities that allow “seamless integration” with SolidWorks, notably its new automation functionality, GibbsCAM Feature Manager, which reads and preserves features from SolidWorks files.

Feature Manager will make it possible for NC programmers to read features from the SolidWorks Feature Tree, such as extrusions, patterns, and revolved features, easily identify and select areas for machining, and apply machining processes required to make the part.

A singular benefit to users is GibbsCAM’s ability to handle the engineering changes that require modifying a part. When an updated part file is transferred into GibbsCAM, it identifies changed features automatically and updates all machining processes “with one or two clicks,” according to the developer. This makes programming faster and results in more accurate parts produced more quickly.

SolidWorks users also benefit from the user interface, making it easy for designers and manufacturing professionals to learn, and to use, Gibbs claimed.

Ease, speed, efficiency

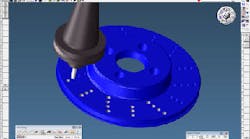

At SolidWorks World 2013, Aughinbaugh demonstrated a SolidWorks part with pockets and other complex features. After loading the part into GibbsCAM and machining it, he showed the ease, speed and efficiency of reading features from the Feature Tree and programming them. To demonstrate how GibbsCAM saves valuable time with an updated part, he showed how GibbsCAM reads the revised part, automatically recognizes changes, updates the machining processes and generates a new NC program. It illustrated the value of the integration between SolidWorks and GibbsCAM in family-of-parts programming and providing quick response to engineering change orders.

Other time-saving functions for SolidWorks users are GibbsCAM’s Automatic Feature Recognition (AFR) and its Hole Manager: the latter integrates with the SolidWorks Hole Wizard to read, recognize, and machine holes automatically. Hole Manager reads all attributes applied to holes created by the SolidWorks Hole Wizard, and automatically generates tool lists and processes right down to the finished operations.

GibbsCAM also preserves colors applied to SolidWorks models. Because colors applied in the design process often convey information about manufacturing processes, preserving these colors improves communication between design and manufacturing, reducing errors and speeding up programming time. In combination with Feature Manager’s reading of solid features from the Feature Tree, GibbsCAM AFR and Hole Manager simplify solids machining and time set-up time for the SolidWorks user.