Producing near-perfect fluid check valves

According to Promess, its electromechanical assembly press produces check valves with ±2-psi tolerances.

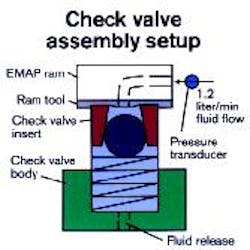

VALVE MANUFACTURERS CAN NOW inspect parts during assembly rather than after thanks to an electromechanical assembly press (EMAP) from Promess Inc., Brighton, Mich. The process lets check-valve companies make nearperfect valves at ±2-psi tolerances.

EMAP uses no pneumatics or hydraulics — instead, press motion is initiated by a servomotor and ballscrew. A computer monitors ram position and pressing force and accepts data from additional monitoring devices. To make a check valve, the EMAP is equipped with an attachment that pumps fluid through the valve at 1.2 liter/min while it is in the press.

Sensors relay information on fluid flow and valve-release pressure to the EMAP's controller. While the valve is assembled, the system monitors the valve-release pressure. To compensate for variations in the valve components that affect release pressure, EMAP compresses the ring inside the valve to increase its resistance. It uses a press-measurepress cycle to force the insert into the valve body until it reaches the targetrelease pressure of 1,000 psi.