How straight will the hole be? This is a critical question to answer in most deep hole drilling boring and machining applications, answering it with assurance cuts across the critical connections between design, project management, and manufacturing. In the third installment of this series we explored Deep Hole Geometry as Specified, with emphasis on the balance of cost-effectiveness versus feature control, considering the range of form attributes. Here, our attention is focused on the bore, considering the range of variation and precision available as machined.

Given the exact specification of rough- or finish-bored holes as conveyed by drawings and other controlling documents, such as purchase orders, a manufacturing plan can be developed. Machine shop operations available for generating or improving deep bore straightness in order of accuracy include:

• Straightness from drilling and trepanning;

• Straightness from mechanical straightening in a press;

• Straightness from finish boring and pull boring;

• Straightness and roundness from deep boring in a lathe;

• Roundness and uniform finish from honing; and,

• Concentricity from other machining in a lathe or milling machine.

Along with a machining plan, an inspection plan enables and verifies the meeting of all requirements.

In addition to micrometers, calipers, roughness testers, indicators, and scales, deep bores may require special equipment such as bore gages, borescopes, ultrasonic equipment, and other special gages to verify size, finish, location, and runout over the complete inside and outside of the part.

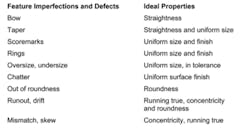

An important goal for manufacturers is to produce parts without variation. In reality, as with most machining operations, deep-hole bores may have variations within tolerance or beyond tolerance. It is important to understand possible variations and plan to allow or prevent them as required. Variations can be measured and described as follows:In rough-bored holes with wide tolerances and no finish requirement, bores may be produced in a single operation and with little concern for rings, chatter, score marks, or other imperfections. As we observed in Part 3 of this series, stock may be required to allow for significant runout.

In finish-bored holes, better straightness, roundness, concentricity, and tight tolerances can be generated. Recognize that as demands of tolerances, lengths, and complex geometry increase, so does the cost of machining and verifying the range of finished attributes.

In many cases, a balance can be struck with strategies to simply drill or trepan, hone, and machine true. For example, consider a workpiece that is Solid H13 tool steel, 14 in. diameter by 80 in. or 2 m long.

The desired part is produced with a through hole finishing at 5.118 in. or 130 mm, and OD of 13.78 in. or 350 mm. Tolerances are ±0.005 in, and the desired runout is 0.040 in. max., or 1 mm. This part can be drilled at a size just under tolerance, honed for final size, and the OD can be turned true to the bore to reduce runout from the drilling operation.

In this example, the drill removes the stock with adequate straightness, perhaps as much as 0.060 in. wall variation at the exit. The hone improves finish and roundness while achieving a uniform finish size. The turning operation reduces bore runout in the worst areas. Runout is independently verified with an indicator throughout the bore. It is very unlikely that runout will exceed 0.010 in. in any spot, but it could be as much as 0.040 in.

Given tighter tolerances, such as runout requirement of 0.003 in. or better for the same H13 part, a new process must be used.

For Tighter Tolerances ...

One method is to drill an initial through hole and then bore in a lathe 40 in. from each end. OD turning may occur before boring to achieve more even cuts. Then, the bore may be finished in a hone to blend the center and achieve a better finish, if needed. Runout is verified again, and should come in under 0.003 in. over the entire length of the bore.

Total indicator runout is less than the tolerance in this case, which allows the straight bore to be located higher in the size tolerance if a blemish such as a ring or chatter develops at the low end of the tolerance.

Bore size is measured all thorough the part with a bore gage at different clock positions verifying size tolerance and measuring the roundness of the bore. Still other deep boring processes must be used if length here is double or triple to 240” and beyond.

The part shown in the photo above is a 316 stainless steel cylinder, 144 in. long with a bore size of 8.5 in., and with a main section wall thickness of 1.5 in. The part was finish-bored, honed, and machined at American Hollow Boring Co. with total indicator runout under 0.010 in. in the bore. With the bore complete, all other finished features were made to the drawing.

We have seen that many methods and tools are available to achieve and verify the significant requirements of deep bores as machined. With clear communication, confidence, and trust, great results are achievable. This is collaboration of engineering, project management, and manufacturing at its best.

For more detail on the subject of concentricity in deep bore machining, please read the previous installments in this series.

Geoff Ginader is the president American Hollow Boring, an independent machine shop specializing in deep-hole drilling and large part machining for industrial manufacturing ranging from heavy machinery to defense projects. He enjoys solving complex machining problems, and experts at AHB are available to review specific projects.

The first installment of this series, “How Straight Will the Hole Be?”, is available here. Part two, “Beyond the Rough, Finish-Bored Hole Straightness,” is available here.

Part three, “Deep Hole Geometry, As Specified,” is here.

For further reading on this topic, American Hollow Boring recommends “Dimensioning and Tolerancing: ASME Y14.5M-1994 (Engineering Drawing and Related Documentation Practices, in. American Society of Mechanical Engineers (ASME), 1995, ISBN-10: 0791822230.