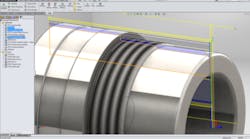

Designers and manufacturing programmers who hold on to distinct concepts of CAD and CAM had better make room for a new disruption to that way of thinking: Autodesk recently rolled out Inventor HSM, “a truly integrated CAM” it claimed will help machinists, designers, and engineers turn CAD designs into manufacturable parts by its ability to generate machining toolpaths directly within the design program.

Inventor is that program. It is the Autodesk platform that presents part designers tools for 3D mechanical design, documentation, and product simulation. It is capable of digital prototyping, designing can be followed by validation, still within the Inventor platform.

Now comes Inventor HSM, the integrated CAD/CAM program that had a beta launch last summer. The current release represents the first commercial availability.

Autodesk is not alone in the effort to bridge the distinction between CAD and CAM, but it has made its effort fairly explicit. That started with its acquisition of HSMWorks, in 2012, and continued with the more recent takeover of the Delcam family of design, manufacturing and inspection software products. (Delcam remains a wholly owned subsidiary and continues to develop and support a series of CAD/CAM programs for different manufacturing specialties.)

“In the manufacturing world, quality is critical,” said Carl White, senior director of manufacturing engineering at Autodesk. “Inventor HSM will help users manufacture high quality finished parts, while saving valuable time and resources.”

Inventor HSM 2015 includes a full license of Inventor 2015 software, so subscribers have access to the full CAD/CAM package. Among the programmable functions are 2.5D, 3D, and 3+2 toolpath options and settings, for optimized surface finishing.

Simulation tools help users to verify machining processes prior to the CNC machining stage. And, customizable post-processors and a “powerful” CNC editor allow the users to establish their own programming sequence for the CNC.

In its introduction of the “integrated CAM” program Autodesk has downplayed the distinction between designing and programming for production, and emphasized instead the fluid nature of design work within the accelerated pace of product development and the expanding range of manufacturing capabilities. The growing importance of 3D printing is evidence of the equal necessity of design work and machine programming, and that consistency is just as relevant for CNC milling, turning, and cutting. All manufacturing is digital, goes the argument, and that defines the need for integrated CAM functionality.