Even the best students need to check their work with an instructor. The analogy may not be perfect, but machine shops will recognize the need to stay fully informed of the capabilities (especially the frequent updates) of the CNC software programs they adopt. Investing the time to learn how to use the latest software technology to its full potential is essential for manufacturers to maintain the efficiency they expect, and to ensure maximum profitability.

At least that’s the new outlook for a British machine shop specializing in complex, high-value components.

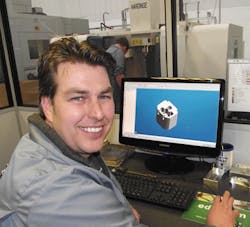

Promach 3D Ltd. is a subcontracting precision engineering shop in Derby, England, and a user of Edgecam, Vero Software’s CAM program that combines sophisticated toolpath generation with CAD integration. Edgecam is used worldwide in various industries, providing a complete suite of milling, turning, and mill-turn programming.

The machinists at Promach 3D discovered they were missing out on 22 features of Edgecam during a typical scenario of milling just one part.

“We always have the latest release, but haven’t had time to attend training courses or user group meetings,” owner Matt Fazekas explained. “That’s going to change now. We’ve definitely seen the light when we were shown just how far we’d slipped behind in terms of using Edgecam to its full potential, and what we were missing out on.”

He described the “tricky balance” for machine shops, between the daily tasks of running and keeping up with the pace of programming advances from developers like Vero Software. Still, he acknowledged an understanding of what the software is capable of accomplishing, and called keeping updated on those developments an ‘absolute priority.’

Areas of expertise

Promach 3D’s areas of expertise are small-batch projects for motor sports vehicles, aerospace, and rail industries. It manufactures a range of structural and aerodynamic parts that are attached to the engine or gearbox, or support wings and carbon-fiber parts on Formula 1 cars.

And, Derby being a center for the British aerospace sector, Promach 3D is called on regularly to machine full mock-ups of parts such as turbine blades and drums, for development and testing.

Derby also is a hub of the U.K. rail industry, and Promach 3D manufacture fixtures, gauges, calibration equipment, and brackets for testing and maintaining track.

Having always used Edgecam, the shop’s owner said it has been vital to its successful business. “We just couldn’t produce the parts we do, without it,” said Matt Fazekas. Because a lot of their work is up to five-offs, Edgecam helps them to produce what could be perceived as five-axis jobs on a three-axis machining centre.

“It just means tilting the job one known reference point,” he noted. “We replicate it on Edgecam and program from that. It involves a few more set-ups than we’d have on a full five-axis machine, but the surface capability that Edgecam provides more than handles that.”

Fateful visit

Still, the fact that Promach was using only part of Edgecam’s extensive capabilities came to light during a visit to the shop by Mike O’Neill, an engineer for Vero Software.

“We showed him a typical milling scenario using Edgecam with one of our three-axis machining centers, and there were so many features we weren’t using properly … or didn’t even know about. Edgecam was doing everything we wanted it to, but there are so many shortcuts and more efficient ways of doing it.

“We’re always asking ourselves how we can do things better without spending hundreds of thousands of pounds,” he recalled. “We’ve got the machines and we’ve got the software. Now, we need to invest some time in fully understanding the software’s potential and working smarter with it.”

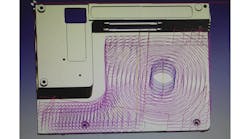

Among the 22 items highlighted in that single machining scenario is “render by slope,” the ability to see at a glance whether a surface that appears to be flat has a slight curve. Also revealed was the “update stock” function: “Where there are a lot of machining instructions and we just want to prove out part of it, we can now do so much, then update the stock, and we don’t have to revisit those machining instructions,” Fazekas said. “This saves a lot of time on the simulator.”

Loading IGES to Edgecam as a solid model was another revelation. “I wasn’t previously aware of that,” he said. “I always loaded it into Part Modeller first, and created the solid model there, so that’s saving us a lot of time. STEP files go straight into Edgecam, too.”

Fazekas said creating geometry from a silhouette is a significant enhancement to Promach 3D’s previous method of finding geometry on a solid. This has taken on even more importance as they have recently invested in a powerful Sodick wire EDM machine.

Still another important discovery has been “background processing.” “I wasn’t aware of that previously,” he admitted. “If we’ve got a lot of machining to do, with a lot of data, we now switch the background processing on before we start, and that saves a lot of time.”

Avenues for learning

Edgecam provides a number of avenues for users to learn about the enhancements and new functionality in the twice-a-year updates, and Matt Fazekas is committed now to make full use of them.

When a new release is issued, a series of training courses provides information on ‘What’s New.’ “In the past I found it difficult to attend due to time constraints and intended to read up on what's new in my own time,” he said. “These courses, I now deem as essential, and figure as one of our main priorities.”

Webinars and user-group meetings also are offered, the former to demonstrate best practices for specific function and to demonstrate new releases; and the latter being one-day seminars with presentations for users to gain more product knowledge.

Last, the software developer’s support desk/customer portal provides Edgecam knowledge on-demand. “It’s very useful to go on the forums, post questions and get answers from other users,” Promach 3D’s owner Matt Fazekas agreed.