Manufacturer Adds Metal AM, with Help from 3D Systems

Additive manufacturing group 3D Systems is supplying two metal-printing systems to a Precision Resource as part of a “strategic partnership” that will introduce additive manufacturing capabilities to the fineblanking manufacturer. Two 3D Systems DMP Flex 350 Dual 3D printers will be installed as part of the workflow Precision Resources in Huntington Beach, Calif.

“Bringing together the industry-leading technology and applications expertise of 3D Systems and Precision Resource will deliver increased quality, improved total cost of ownership, reduced time to market, and minimized supply chain disruption,” according to 3D Systems’ Jeph Ruppert, vice president, technical business development.

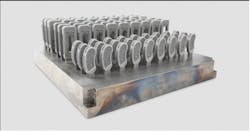

The DMP Flex 350 is a direct metal laser sintering (DMLS) system that applies high-precision laser power to metal/alloy powders to convert CAD data into successive layers that form complex metal parts, for product development or series production. According to 3D Systems, DMP platform’s “quick swap build modules” and powder recycling help accelerate production, and a central server manages print jobs, materials, settings, and maintenance.

In its announcement, 3D Systems noted that its Application Innovation Group engineers worked with Precision Resource to develop the new installation, which it predicted will offer new solutions for customers and open new markets for the manufacturer.

Precision Resource is a developer of fineblanking technologies and manufacturer of precision parts for automotive, aerospace, and medical device manufacturing, among other sectors, producing millions of fully finished components annually. The organization operates over 100 fineblanking presses along with finish machining and inspection technologies, capabilities that will be extended with metal additive manufacturing.

“This partnership allows us to leverage the latest advancements in metal additive manufacturing, further positioning Precision Resource at the forefront of technological progress,” stated Chris Gratton, general manager, Precision Resource. “This expansion into metal additive printing underscores Precision Resource’s ongoing commitment to providing exceptional value to our clients, customers, partners, and stakeholders.”