GE Aviation reported progress in testing a demonstrator version of its Advanced Turboprop (ATP) engine, one that includes 12 parts produced by additive manufacturing. The parts comprise 35% of the total assembly, and according to GE Aviation, reduce the ATP's weight by 5% and provide a 1% improvement in specific fuel consumption.

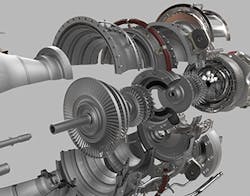

The development project aims to produce a new turboprop engine that will power a new Cessna Denali single-engine aircraft. That engine, which GE Aviation and Cessna parent Textron Aviation announced a year ago, will have a range of 1,600 nautical miles and speeds higher than 285 knots. GE has said the new ATP engine will include a rugged, modular architecture based on its CT7 turboshaft engine, with a titanium compressor for lightweight power generation, cooled turbine blades for higher thrust and fuel efficiency, and integrated electronic propulsion control.

The 1,240SHP-rated ATP is GE Aviation’s first entry in a family of turboprop engines in the 1,000-1,600 SHP range, being developed for business and general aviation aircraft. These designs reportedly will offer a 16:1 overall pressure ratio, so the engines can achieve fuel burn rates up to 20% lower and cruise power up to 10% higher than current offerings in the same size class.

The new engines also project to offer 4,000-6,000-hour maintenance time between overhauls.

Additive manufacturing technology has been critical to the engine development process. GE Aviation has said the ATP series will include more 3D-printed components than any production engine in aviation history. A total of 855 conventionally manufactured parts will be reduced to 12 additive-manufactured parts, including, sumps, bearing housings, frames, exhaust case, combustor liner, heat exchangers, and stationary flowpath components.

"With subtractive-manufactured parts and assemblies, you traditionally use bolts, welds, or other interfaces to attach the parts together, which adds weight to the engine," according to GE Aviation’s Gordon Follin, ATP Engineering general manager. "On the ATP, additive (manufacturing) reduces weight by eliminating those attaching features while also optimizing design of the parts."

The additive-manufactured components for a-CT7 and ATP tests are built at GE Aviation's Additive Development Center in Cincinnati. The a-CT7 tests are conducted at GE Aviation's facility in Lynn, Mass.

Additive manufacturing also allows GE Aviation to expedite the engine certification efforts. GE recently completed ATP combustor rig tests six months ahead of schedule, and the ATP combustor liners were printed in merely two days.

In the months ahead, GE will run a second test of the a-CT7, involving even more additive-manufactured parts, to expand the technology to additional structures and assemblies.

GE indicated it expects to run its first full ATP engine test by the end of 2017 in Europe.