The Federal Aviation Administration (FAA) selected eight manufacturers to receive $100 million in contracts to develop and demonstrate technologies that reduce fuel consumption, emissions, and noise, under the second phase of its Continuous Lower Energy, Emissions, and Noise (CLEEN II) program. The companies include Pratt & Whitney and UTC Aerospace Systems' Aerostructures business, as well as Aurora Flight Sciences, The Boeing Co., GE Aviation, Delta TechOps/MDS Coating Technologies/America’s Phenix; Honeywell Aerospace, and Rolls-Royce Corp.

FAA’s CLEEN II program aims to reduce commercial aircraft fuel-burn rates by 40%, to cut NOx emissions during takeoff and landing by 70%, to lower noise levels by 32 dBs, and to expedite commercialization of “drop-in” sustainable jet fuels. FAA aims for the CLEEN II aircraft technologies to be ready for commercial introduction by 2026.

CLEEN II follows the original CLEEN public-private partnership linking the FAA and aerospace OEMs’ and suppliers’ “efforts to make aviation more environmentally friendly.” Starting in 2010, the CLEEN partnership conducted nine projects covering energy-efficient aircraft technologies and sustainable alternative jet fuels.

Some of these technologies will enter service starting next year, according to the agency. The new partnership programs also will continue for a five-year period.

FAA said the CLEEN II partners companies would match or exceed FAA’s investment, totaling about $200 million, to develop energy-efficient airframe and engine technologies. Each effort will include full-scale ground and/or flight test demonstrations intended to bring the product to market.

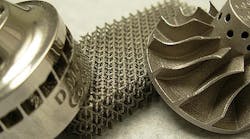

According to Pratt & Whitney, in the CLEEN II program it will continue developing technologies applicable to ultra-high bypass ratio aircraft engines, specifically its PurePower® Geared Turbofan™ (GTF) series. The studies are aimed at enhancing the thermal efficiency of the engine core, research that P&W said would be complementary to its earlier CLEEN-related project.

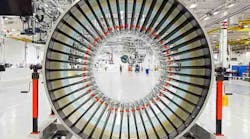

Testing for the research project will be done on Pratt & Whitney’s PurePower PW1000G Geared Turbofan engine. The PW1000G family is characterized by a gear system that separates the engine fan from the low-pressure compressor and turbine, so that each module operates at its optimum speeds. This allows the fan to rotate slower while the low-pressure compressor and turbine operate at a high speed, increasing engine efficiency and reducing fuel consumption, emissions, and noise.

According to Pratt & Whitney’s Alan Epstein, v.p. - Technology and Environment, "The PurePower Geared Turbofan engine, which is meeting or exceeding specifications for fuel burn, noise and emissions, is a prime example of how our suite of technologies continues to shape the aviation industry and provide customer value."

Pratt & Whitney also is a subcontractor on another CLEEN II project involving its sister company, UTC Aerospace Systems. That effort is focused on nacelle technologies and on UTC Aerostructures' the ecoIPS™ (Ecological Integrated Propulsion System) to reduce fuel burn and noise.

As for the UTC Aerospace Systems' Aerostructures research, "the advanced technologies we will develop as part of the CLEEN II technology demonstrator will build upon our design innovations currently being deployed on the world's newest airplane platforms, such as the Airbus A350 XWB and A320neo, the Boeing 787 Dreamliner, the Bombardier CSeries and the Embraer E2," said Marc Duvall, president.