GE Aviation reports its GE90 will be the first of its commercial jet engines to manufactured with a housing component produced by additive manufacturing. The U.S. Federal Aviation Administration in February certified a new, improved T25 engine sensor to be retrofitted to over 400 of the GE90-94B engines now in service.

The General Electric GE90 is a family of high-bypass turbofan aircraft engines, the largest produced by GE, and built for the Boeing 777 long-range wide-body aircraft. In service commercially since 1995, it reportedly is world’s largest turbofan engine.

The T25 engine sensor provides pressure and temperature measurements for the engine’s control system.

GE noted that the GE90 engine was the first jet engine to incorporate composite fiber polymeric material on its front fan blades when it was introduced 20 years ago.

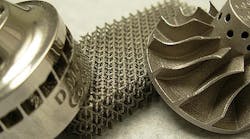

Additive manufacturing is quickly gaining acceptance in jet engine production, for its design flexibility, material selection, and production cost advantages. The term refers to various production methods, including stereolithography for polymer materials, and direct or selective laser sintering for metals.

GE Aviation has been in the forefront among all manufacturers adopting additive manufacturing for high-volume production. It identified additive manufacturing for fuel nozzles more than two years ago.

Several GE engines now in development will incorporate the AM methods, including the LEAP engine (a product of GE Aviation’s joint venture CFM International engine) for narrowbody aircraft and the new GE9X for the Boeing 777X aircraft,

“Additive manufacturing has allowed GE engineers to quickly change the geometry through rapid prototyping and producing production parts, saving months of traditional cycle time for the T25 sensor housing without impacting the sensor’s capabilities,” stated Bill Millhaem, general manager of the GE90/GE9X engine program at GE Aviation.

GE Aviation also reported that its production rates, and those of its parts suppliers, for jet engines and components are setting new records for volumes: Its total backlog for GE jet engines (including engines designed by CFM International) now exceeds 15,000 units, representing more than $135 billion for equipment and services. That is a 25% rise in the past two years. GE Aviation’s jet engine deliveries (commercial and military) have grown from 3,000 in 2010 to about 3,700 in 2014, it reported, and that level is forecast to be maintained in 2015.