General Motors and Stellantis are among the new investors in a Minnesota business that proposes to manufacture permanent magnets to power electric vehicles without resourcing “rare-earth metals.” Niron Magnetics raised $33 million in additional funding it states will be used to expand its current pilot plant and scale manufacturing capacity for its “Clean Earth Magnet®.”

Niron Magnetics did not detail the plan for its commercialization or scaling its production.

Neither Niron nor the automakers identified the value of their individual investments. Published reports indicate that GM’s investment amounts to $7 million, while Stellantis is in for $5 million..

Permanent magnets, made from magnetized rare-earth metals – e.g., terbium, dysprosium, praseodymium, and neodymium – are the basis for one type of electric motor preferred for powering EVs thanks to their efficiency versus induction or other types of motors.

However, rare-earth mining and extracting, and subsequent manufacturing processes, are expensive, labor intensive, and environmentally detrimental. Even more concerning is that most rare earths are sourced from China, which requires export permits for critical materials, creating an unstable supply chain and threatening the automotive industry’s reliance on EV technology that is the foundation for the future they have planned.

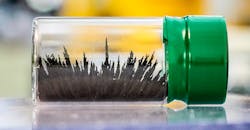

Niron Magnetics’ magnet technology is based on recycled iron nitride material, which it claims produces magnets with “inherently high magnetization” and will be the basis for “a revolution in the design of new electric motors and generators.”

“We were drawn to invest in Niron by the impressive sustainability benefits that its Clean Earth Magnet technology offers for vehicles and the inherent scalability of their solution,” stated Adam Bazih, managing partner at Stellantis Ventures. “Making powerful magnets from plentiful commodity materials decouples new production from rare earth mine development and lowers overall environmental impact, which directly aligns with Stellantis’ commitment to reach carbon net zero by 2038.”

Niron has stated its Clean Earth Magnet is more magnetic than typical permanent magnets made using neodymium and praseodymium.

In addition to its capital investment, GM and Niron have a strategic partnership agreement to co-develop Clean Earth Magnet motor technology that can be used in future GM EVs.

“We believe Niron’s unique technology can play a key role in reducing rare earth minerals from EV motors and help us further scale our North American-based supply chain for EVs,” stated GM Ventures president Anirvan Coomer. “Our path to an all-electric future will be enabled not only by our own research and development efforts, but also by investing in next generation technology from startups and established companies outside our four walls.”

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.