GE Aviation concluded the first testing phase on its second XA100 adaptive cycle engine as part of the U.S. Air Force’s Adaptive Engine Transition Program (AETP). The tests took place at GE’s Evendale, Ohio, altitude test facility, collecting what GE called “high-quality performance data validating the engine’s transformational propulsion capability.”

The XA100 is a three-stream adaptive-cycle engine developed at GE Edison Works that can adjust the bypass ratio and fan pressure to increase fuel efficiency or thrust, depending on the scenario. According to GE, the XA100 is uniquely designed to fit both the F-35A and F-35C without any structural modifications to either airframe, to improve aircraft range, acceleration, and cooling power, and enhance its combat effectiveness.

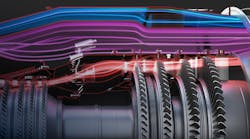

GE noted that the engine makes extensive use of advanced component technologies, including ceramic matrix composites, polymer matrix composites, and additive manufacturing.

The tests began last December, and according to the developer the engine’s performance and mechanical behavior were consistent with pre-test predictions and in line with the AETP goals.

Phase 2 tests will begin at USAF advanced testing facilities at Arnold Engineering Development Complex (AEDC) during Q1 2022.

“Phase 1 testing allowed us to further characterize the operation of the engine and puts us in a great position to begin Phase 2 testing at AEDC,” stated David Tweedie, GE Edison Works’ general manager for Advanced Combat Engines. “We continue to burn down risk with full-scale engine testing, which is why the XA100 is the lowest risk, most capable, and fastest approach to keep the F-35 a preeminent fighter platform for the long term.”

GE’s XA100 became the world’s first ever flight-weight, three-stream adaptive cycle engine in December 2020 before initiating tests on its second engine in August 2021. GE’s engine is uniquely designed to fit both the F-35A and F-35C without any structural modifications to either airframe, enabling better aircraft range, acceleration, and cooling power to accommodate next-generation mission systems.

“Between the step-change fuel efficiency improvement and enhanced durability of our advanced materials, this engine provides the maximum opportunity to increase readiness and reduce operational and lifecycle costs,” Tweedie added. “No upgrade of a legacy propulsion system can simultaneously provide the revolutionary improvements in fuel efficiency, thrust, power and thermal management, and durability as the XA100 engine.”