Larger-Scale Compact Machining

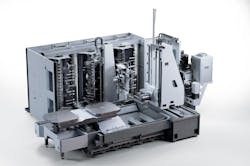

STARRAG recently presented its new Heckert H100 compact machining center to the public for the first time. With a pallet size of 39 in. (1,000 mm), it will replace the previous Heckert HEC 1000 4-axis machine.

The new Heckert H50 to H100 compact machines offer maximum precision, performance and speed in as little space as possible.

The Heckert H100 has dimensions of 350 x 181 in. (8,900 mm x 4,600 mm) and enables travel paths of 69 in. (1,750 mm) along the X axis, 51 in. (1,300 mm) along the Y axis and 55 in. (1,400 mm) along the Z axis. Optionally, the Y-travel can be extended up to 55 in. (1,400 mm) and the Z-travel can be extended up to 71 in. (1,800 mm.) The displacement circle diameter is 79 in. (2,000 mm.)

The Heckert H100 is suitable for large parts and, with a loading weight of 8,818 lb. (4,000 kg), and also suitable for heavy parts that otherwise would be processed on a large machining center.

According to the developer, the cost savings start with the initial investment and continue with transport costs, the foundation and machine installation, and continue to the machining process.

The new Heckert H100 compact machine improves on the HEC 1000, in many respects. It is easier to automate, and this is ensured by extended clamping hydraulics and simplified interfaces to pallet storage systems and robot cells. Improved integration with customer infrastructure is accomplished with central connections for technological cold water, cooling lubricant, and data exchange. There is also a larger selection of spindles and much more.

The new Heckert H100 compact machining center offers customized solutions for highly productive machining, particularly in the area of commercial vehicles and in high-precision mechanical engineering.

Learn more at www.starrag.com