2025 CAD/CAM Release Adopts AI Features

GIBBSCAM launched the next release of its CNC machine programming platform – GibbsCAM 2025 – which includes functions enhanced with Artificial Intelligence, incorporates new turning technologies, and offers wide access to manufacturing and tooling expertise. GibbsCAM continues to integrate Sandvik's cutting-edge manufacturing and tooling know-how into its development efforts, so machinists gain improvements in efficiency and productivity, both in engineering and production.

“GibbsCAM 2025 marks the beginning of a new era in terms of AI support for manufacturing. Now, we're the first CAM system in the market offering an AI copilot based on Microsoft’s Azure Open AI,” according to GibbsCAM president Thorsten Strauß. “Additionally, thanks to our cooperation with up2parts, we can provide our customers now with a powerful AI-based toolpath generator. These are significant steps for the CAM world, and for GibbsCAM also.

GibbsCAM 2025 provides full support for Sandvik’s OptiThreading, following the introduction of Sandvik Coromant's PrimeTurning™ technology into GibbsCAM 2023, and enhanced Y-axis turning capabilities (simultaneous sweeping) added in 2024.

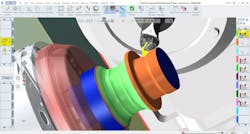

With the insert positioned in the Y-Z plane, Y-axis Turning effectively directs the primary cutting forces into the milling spindle, providing exceptional stability. This yields superior chip control, improved surface finish, and increased cutting speeds. Furthermore, the inclusion of a third axis for tool rotation allows for optimal positioning of the tool, for cutting of intricate shapes with a single tool. This also enables a seamless "sweeping" motion for cutting complex shapes, preventing any blend marks and ensuring precise control of the insert wiper effect.

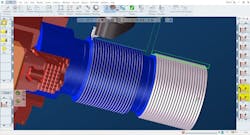

Sandvik Coromant’s OptiThreading provides thread-turning functionality. GibbsCAM’s new turning strategy for OptiThreading enables controlled chip breaking to eliminate long stringy chips that can damage a component’s surface and interfere with the cutting zone. It is just as suitable for simple threads as it is for cutting complex thread profiles, in high-strength alloys or exotic materials.

Using cutting data from the CoroPlus® Tool Library, OptiThreading lets users develop optimized thread-turning tool paths that specifically overcome the challenge of chip control with these operations. This is achieved by specialized GibbsCAM tool paths that use controlled, oscillating movements in and out of the cut for interrupted cuts on all passes except the last one. The result is controlled chip control for improved component quality, faster cutting speeds, and less manual work by reducing the need to manually clear long chips during the machine run cycle.

For both Y-Turning and OptiThreading GibbsCAM 2025 offers best-in-class programming strategies unlocking the full potential of these fantastic technologies.

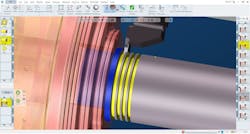

With Rib Cut Plunge, GibbsCAM 2025 offers another new turning strategy. This special turning strategy for roughing reduces tool deflection, improves tool life, and guarantees excellent chip control. Within a preliminary operation, the tool repeatedly plunges into the part at full engagement to create a series of cuts with each cut more than a tool-width away from the previous one. The following pass cuts the remaining ribs at a 30-50% increase in feed.

As the preferred CAM solution for Swiss-type machining GibbsCAM 2025 introduces a new option for the headstock origin. This allows the NC programmer to define a value for the distance between the front of the guide bushing and the headstock’s 0 position. With that, the correct positioning of simulation bodies on the headstock axis becomes easier. It provides a more intuitive interface in the dynamic coordinate definitions for Swiss-style machines.

Fast and effective AI support

The introduction of the GibbsCAM Copilot is part of Sandvik’s commitment to embrace AI for the user’s benefit. It represents just the start of a longer-term initiative to maximize productivity and profitability by implementing AI technology. Accessible directly from the Online Help menu, GibbsCAM Copilot uses Microsoft Azure Open AI on top of a dedicated database, trained by the GibbsCAM team, to offer rapid user support at any time without the need to hunt through documentation or reach out for first-line support.

GibbsCAM 2025 offers a new plug-in to up2parts autocamp, so this tool for automized NC programming is available for its users. Utilizing 3D models with tolerance information, up2parts autoCAM automatically generates proposals and recommendations for six-sided machining, including clamping, machining steps, operations, and tools by using AI technology. This leads to reduced engineering time by automizing the NC programming based on geometry and PMI. GibbsCAM users can upload the information into GibbsCAM, post process immediately, or simulate and edit before if needed.

Visualization of multi-flow operations: Within its Multi Task Machining solution, GibbsCAM supports the complex machining centers with an unlimited number of axis and any axis orientation. To always give the user the best view on the defined multi-flow operations, GibbsCAM 2025 provides additional Operation Tile Modes to display multiple flows independent of the MTM Sync Manager. Users can choose to Show All Flows for a comprehensive view, Show Each Flow for focused management, or use Sync Flow Mode to coordinate displays across operations, improving organization and control of multi-flow processes.

Facet body function: Facet bodies can play an essential role in modern CAM workflows, bridging potential gaps between design and manufacturing, and enabling precise and optimized production processes. GibbsCAM 2025 provides users with powerful tools for manipulating facet body models without the need for external CAD software.

The new Facet Body Modelling palette supports a wide range of specific editing functions, including Tesselate, Simplify, Re-facet, Heal, and Smoothing of facet bodies. Many existing Solid Modeling functions now support FB such as Booleans, Slice, Separate, Offset/Shell, History, and more. With this new functionality, GibbsCAM users can now easily work with FB models such as parts, machine components, fixtures, and In-process Stock Models directly within GibbsCAM.

Powerful tool management: GibbsCAM 2025 brings further improvements to tools and tooling. The new Order Tool utilizes important information from tool libraries, such as the item/catalog number and manufacturer. This information will be gathered through a tool catalog integration, including trusted sources like CPTL, Garr Tool, Harvey Tool, etc. Upon clicking on the icon, the user will be directed to purchasing/ordering pages, in a specific Tool Library site, where that tool originated from.

Simulator enhancements: The Simulator in GibbsCAM 2025 offers enhanced features for control and visibility during simulations, ensuring program accuracy. A new stop option allows the simulation to pause before each operation. Additionally, a new scrolling bar in the Sync Manager tracks simulation progress, providing real-time feedback for MTM machining operations. The innovative "Rotary Hint" option graphically displays the spindle direction for both Turning and Milling. To enhance safety, collision detection, and alerts are now activated by default.

“By releasing these innovative solutions, we demonstrate our ambition to extend our technology leadership in this area. For sure, completing our joined developments together with Sandvik and numerous other improvements all over the GibbsCAM suite makes us more than excited to make this comprehensive update available now for our customers,” Thorsten Strauß added. “And I can already promise that we are already working on additional powerful improvements now."

Learn more at www.gibbscam.com/en/whats-new