Grinding Technology for High-Quality, Low-Cost Tools

ANCA CNC MACHINES will present several innovations for tool grinding at IMTS 2024 and invites visitors to booth 237406 to experience “the future of tool manufacturing.”

The ANCA GCX machine and gear tool technology is set to redefine production of skiving cutters with a turnkey solution package. To address the complexity of gear tool manufacturing, this offering includes features for the design of gear cutting tools, manufacturing and integrated tool measurement, as well as providing the skiving machine setup parameters.

IMTS visitors will witness how this configuration allows short set-up times, simulation, and monitoring, plus quality-enhancing features like the ANCA Motor Temperature Control (MTC) and integrated balancing (iBalance) for long-term grinding profile accuracy within +/-0.0015mm.

This turnkey package facilitates easy entry into the gear tools sector while ensuring top-quality results.

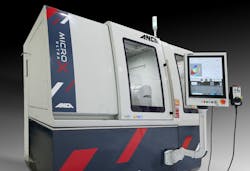

Also demonstrated at IMTS 2024 will be ANCA’s Ultra technology, which combines nanometer control, servo-controlled algorithms and mechanical stiffness upgrades to achieve unprecedented accuracy. The FX7 Ultra and MicroX Ultra demonstrate ANCA's commitment to precision and making possible continuous batch production down to 0.03 mm, setting new standards in tool manufacturing.

As the only micro tool grinder with nanometer control, optimized mechanical layout and axes travel, integrated tool measurement and progressive automation, this six-axis grinder is an ideal solution for volume production of tools down to 0.03 mm.

ANCA’s new EPX-SF stream finishing machine introduces an advanced edge-preparation and surface-finishing solution that addresses productivity targets, delivers superior IP cutting tool performance and succeeds in precision-critical industries – in a design that’s ready to be integrated in automated tool manufacturing systems.

With 11-axis automation and smart recipe fine-tuning, the EPX-SF machine is engineered by tool experts to optimize media usage while providing precise edge control. It is able to reduce edge roughness under 100 nm and refine edge radii to mere microns with controllable K-factor, achieving nano-smooth surfaces and micron-honed edges in record time.

The EPX-SF’s cyclic mode with pulse rotation serves as a potent defense against surface burrs and edge imperfections. With adjustable positive and negative angles, the EPX-SF spindle traverses the optimal cutting path, optimizing potential chip flow and reducing the surface roughness of the cutting workpiece.

Within ANCA’s automation ecosystem, the EPX-SF seamlessly integrates into production lines, operating autonomously with robotic assistance round the clock for tool loading/unloading.

The CPX blank preparation machine is a prime example of how to include the voice of the customer in product development. Tool manufacturers around the world were asked and given their ideal solution for blanks with high material removal rates, application flexibility, and integrated quality control. With features like statistical process control and top surface finishes below 0.2Ra, manufacturers can achieve high productivity at minimal cost with the CPX Linear. Some further application capability will be introduced at IMTS.

Learn more at machines.anca.com