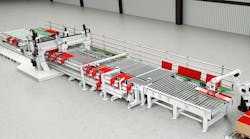

The IMA SCHELLING IMAGIC L1 through-feed drilling machine can be adapted to any requirement in "batch size 1" production, in terms of the type or scope of processing – e.g., drilling, milling, grooving, fitting – or the required performance. This is possible with standard modules that can be put together and supplemented for a specific application over a length of up to three processing bridges.

The wide range of assembly options on both sides of the processing supports allow an optimal division of the processing at any time and, depending on the components, also parallel processing on the front and rear of the support. Whether pure drilling or any combination of milling, drilling, dowellin,g and fitting - the customer's requirements determine the design of the machine.

Up to three machining supports can be installed on one machine. Integration of a milling spindle with a stationary tool changer is also possible. Appropriate parking and maintenance positions of the units ensure easy drill bit changes and good accessibility in the event of maintenance.

The IMA Schelling Group developed the IMAGIC L1 in cooperation with its technology partner, Zimmer Group from Rheinau.

The patented Zimmer transport system with rotating clamping clamps transports the workpieces in a permanent, fixed clamping through the entire system - even with several processing supports. This results in several advantages. The clamping allows the workpiece gaps and thus the chip-to-chip times to be reduced to a minimum. Together with the high dynamics of the entire system, this leads to increased system availability and increased machine performance.

Thanks to its modular design, the IMAGIC L1 can be configured either as a manual or automated drill cell. Integration into complex production lines is also possible without any problems.

Learn more at www-imaschelling-com