INOVATOOLS offers a range of tool concepts for creating complex and/or deep contours at high feed rates and low cutting forces, including trochoidal speed cutting, optimized in terms of SC, geometry, chip clearance, and coating for a variety of materials like special alloys, hardened steel, tempering steel, INOX, general construction steel, aluminum, composite materials and plastic.

“Trochoidal speed cutting” (TSC) combines the ideal cutting speed with continuous, elliptical/circular paths calculated on the basis of the average chip thickness. Its also known as trochoidal milling or slot milling. Compared with conventional full‑slot milling, machining with the smallest possible tools is the most efficient and economical strategy thanks to the near-constant cutting force.

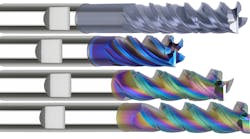

Examples offered by Innovatools include the four-edge SC hybrid milling cutters with the “ultra-smooth VAROCON high-performance coating (595...); the steel and INOX HPC and TSC milling cutters; and the SC dynamic milling cutters (591...; 597...; 598..., 592...), which come in a variety of designs and dimensions for TSC applications in steel, INOX, and GGG.

Thanks to tool designs featuring special, ultra-fine-grain carbide with a balanced mixing ratio, optimized geometries, and chip grooves, as well as high-performance, application-focused coatings, Inovatools’ range of TSC milling solutions set high standards in terms of performance, quality, and integrity.

One benefit of the design of Inovatools’ TSC milling cutters is the optimal chip-breaking characteristics, which result in short, quick-to-break chips. The milling cutter removes all the chips quickly from the contact zone, which also helps to reduce the heat generated during cutting. This protects both the tool and the workpiece. In this way, many Inovatools tools can be operated with high cutting depths, speeds and feeds and with the even distribution of machining forces across the entire length of the cutting edge – and, if necessary, also in dry machining processes.

Inovatools’ range of TSC tools also help to boost performance in the cutting of aluminum, plastic and composite materials like GFK and CFK. The three-edge TSC-SC dynamic milling cutters (2.414...; 2.410...), which are available in diameters of 6 mm to 20 mm, are optimally designed to meet these specialized cutting requirements.

Learn more at www.inovatools.eu