With roots that can be traced back thousands of years, the common gear remains functionally similar to its predecessors. Although there have been some variations introduced throughout the course of history, some of which serve more advanced purposes, the typical uses for gears also have not changed much over the centuries.

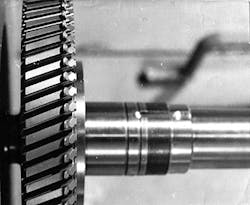

One aspect of manufacturing gears has endured some notable changes, the different finishes applied to different gear types. As individual gears require a particular surface to maintain compatibility with the surrounding components in a specific machine, it's useful for machinists and shop managers to know the differences among some of the most popular finishing processes in use today.

Vibratory finishing is a standard process involving tubs of various sizes that hold both the rough production pieces as well as non-abrasive materials or media: that media applies the abrasive treatment to the parts’ surfaces, which achieves the final finish. The vibratory action of the tubs continues for as long as necessary until the manufacturer achieves the desired result.

The media used in vibratory finishing may be wet or dry, each of these providing different results. Because the tubs are limited in size, vibratory finishing is best used on smaller parts, pieces and tools, including those within the automotive, marine and aerospace industries.

Vibratory finishing may be applied in tandem with 3D printing to bolster the quality of small-scale pieces. Multiple options for wet and dry media are available for deburring processes, all of which are capable of achieving different finishes. It's important to keep in mind that many of these materials are meant for applying a finish to a metal part or object and not a plastic piece, so the results might be slightly different than what you expect.

Centrifugal barrel finishing (CBF) is a high-energy process that has been steadily gaining in popularity over the past few decades. Although it's still not as widely used by manufacturers as vibratory finishing, CBF is catching on with operators who regularly work with parts that maintain extended production cycles or develop specialized surface requirements.

The CBF process may be likened to that of a rock tumbler, although a total of four separate drums mount onto a larger wheel that serves as a sort of Ferris wheel. As the wheel turns, the unfinished production pieces - as well as the finishing media inside the individual drums - tumble until achieving the ideal surface.

Because CBF machines feature a lot of moving parts, they require regular maintenance and, in some cases, repairs. At times some of the parts were difficult to locate, though many different companies now specialize in used parts and equipment.

Turbo-finishing is recommended for manufacturers that want to take advantage of the latest technological advancements will enjoy the process of turbo-finishing. Sometimes known as turbo-abrasive machining, this is a dry method of deburring that uses a fluidic media that can be altered to achieve any number of surface finishes. This process also takes advantage of the increasing potential for process automation and computer control.

Turbo-finishing offers a number of benefits across different industrial sectors, such as diesel automotive and aerospace, among others. It has already replaced the need for laborious hand-deburring of rotors and various parts used in more advanced vehicles, and it’s credited in part for increasing the durability of turbine blades.

Although the machines described here can be seen in nearly any industry that requires high quality and precision machining, understanding that the specific characteristics and applications of each one is critical to ensuring that you're using the right tool for the job. The subtle nuances and distinctions might seem meaningless at first, but anyone who requires an accurate surface finish, a certain level of quality, or increased production timelines will certainly see the benefit.