If a spindle breaks down, what is your plan of action? Is it the most practical and efficient way to deal with a down spindle? Spindles need maintenance at varying intervals, based on the length and design for their operation. Normal use of any machine will cause wear and tear, the spindle being the component that receives the majority of the wear. It is necessary for them to run at the right speeds and feeds to keep the wear minimal. Because of this, a good spindle program should take into consideration the specific operational information of each, individual spindle.

Machine shops and manufacturers need to have a well-planned maintenance strategy in order to be successful and competitive. A faster and newer machine does not automatically mean that your operation will keep its competitive edge. When a spindle breaks down, the operation that manages its machine proactively will reduce downtime and maintenance and repair costs, resulting in an increase of productivity. This will significantly boost the competitive standing of your operation.

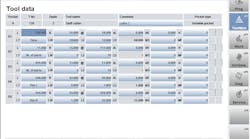

The process of managing your machine includes developing a machine-tool and spindle service program. Establishing such a program, an effective program, is critical for shops aiming to achieve a high level of overall equipment performance.

Overall equipment performance is measured by three factors: asset availability, production, and quality level. The following four programs display different types of procedures undertaken when a spindle fails, ranging from the most basic plan of action to an advanced approach.

1. The emergency program — You can compare the emergency program to hitting a panic button. If an important spindle breaks down, the manufacturer will take whatever steps are needed to get that spindle repaired as quickly as possible. Regardless of the expense, the manufacturer will have it shipped and serviced with the highest-priority.

Repairing the spindle immediately reduces downtime, but the costs add up because of the urgency, making it less practical than other programs. Gilman Precision accommodates this type of program by offering a rush-order service option.

2. The “first in, first out” program — The “first in, first out” program works as if there is no program at all. There are no precautions taken, such as scheduling routine maintenance checkups. Similar to the emergency program, if a spindle breaks down it is simply taken in to be serviced.

The difference is there is no urgency to fix it. This program may be impractical, especially if the spindle that is down is important. There is no priority on the spindle when being serviced, which means it can take weeks or months before it is returned and running again. This can delay production schedules, which can put the manufacturer at a competitive disadvantage.

3. The scheduled maintenance program — Routine maintenance checkups are performed according to the scheduled program. These checkups are scheduled according to the previous maintenance records, and the program provides the spindle with enough attention to keep it running in good operating condition.

However, the program does not take into consideration fluctuating hours of operation, environmental considerations, or whether or not the spindle even needs to be serviced. The problem is the spindle could be running fine, but time and money may be lost because of unnecessary services.

4. The spindle “hotel” program — The spindle “hotel” program expands on preventative measures by coordinating the use of more than one spindle of identical design. The spare spindle acts as a replacement in case the main spindle breaks down. The spare is kept either on site or at a designated repair facility. The advantage this arrangement is that downtime remains low: If the spindle breaks down the spare replaces it and production does not have to stop to wait for it to be fixed.

The downside to such a program is that the amount of capital sitting in the “hotel” could outweigh the convenience of the program. If this is the type of program your operation follows, Gilman Precision will provide its Spindle R&R service, which allows any spindle to be housed for up to 12 months after being repaired.

The most important consideration to factor when deciding on a program is the goals of the plant. The program that is followed needs to align with the operation’s objectives. Deciding which spindle service program is the best fit for the operation should not only align with the goals of the business, but should be individualized to all the spindles.

Monitoring spindles can prevent the unpredictable damage and allow the operation to maximize its production program, and reducing unnecessary downtime and costs can make the operation more competitive. If you are questioning what you are going to do when a spindle breaks down, it is time to implement a strategy that will optimize overall equipment performance.

Chris Hetzer is the CEO of Gilman USA LLC. For more information, contact Doug Biggs at [email protected]; Tel. 262-204-2227